Menu

- Home

- About Us

- Company Style

- Certificate

- Exhibition

- Service

- Delivery

- Responsibility

- News

- FAQ

- Products

- Aggregate Equipment

- Sand Making Plant

- Vsi Crusher

- Aggregate Grinding Mill

- Fly Ash Powder Separator

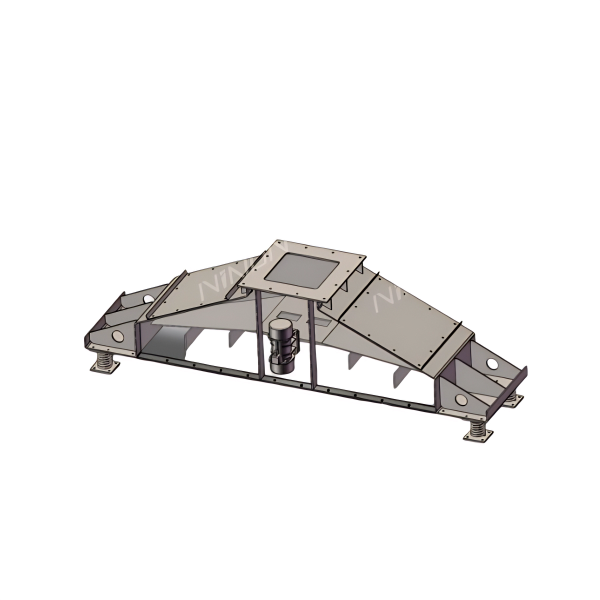

- Vibrating Screen

- Aggregate Processing Equipment

- Dry Mortar Production Line

- Dry Mix Mortar Plant

- Concrete Mixer

- Ultra-High-Performance Mortar Mixer

- Industrial Mineral Processing Mixer

- Waste Recycling Machine

- RAP Asphalt Recycling Plant

- Construction And Demolition Waste Processing Equipment

- Intelligent Control System

- Intelligent Control System

- Remote Operation and Maintenance System

- blog

- Case

- Factory Show

- Factory Display

- Factory Production Work

- Product System Innovation

- Contact Us

Search