Advanced Centralized Control

◆The system features a cutting-edge centralized control architecture, combining an industrial PC, touchscreen interface, and PLC with hot-backup redundancy for uninterrupted performance.

◆It offers one-key startup, mouse-driven operation, and immersive 3D process visualization for streamlined management.

High-Reliability Components & Safety Functions

◆Built with high-performance components from globally recognized brands (Siemens, Schneider, LS, etc.), ensuring durability and reliability.

◆Integrated interlock and safety protection mechanisms safeguard against system faults and ensure stable operation.

Real-time Monitoring and Data Logging for

◆Overload / Overcurrent / Power failure

◆Temperature / Flow / Pressure / Vibration

◆Current / Time / Valve position / Dust filter differential pressure

◆Supports comprehensive data storage, automated report generation, and real-time trend curve visualization.

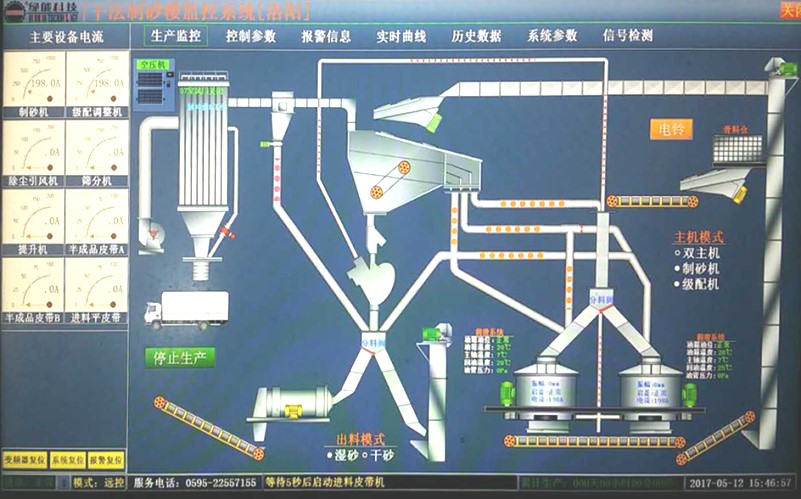

Real-Time Machinery Monitoring Display Interface

Adaptive & Smart Functions

◆Self-adaptive control enables seamless transitions between different raw material processing modes.

◆Memory function allows quick recall of optimized operating parameters for repeat efficiency.

Optional Smart Upgrades

◆Real-time display of gradation curve and fineness modulus

◆AI-powered material visual recognition system for precision classification

Network & Remote Control

◆Fully compatible with DCS integration and LAN connectivity

◆Supports remote monitoring and control via mobile app for operational flexibility

Self-Diagnostic Alarm System

◆Continuous self-monitoring with automatic fault detection

◆Instant alerts for anomalies, enabling proactive maintenance

Intelligent Electricity Management System

Material Recognition & Parameter Memory

◆Identifies and records properties of raw materials and rock characteristics

◆Enables intelligent adjustment of processing parameters for optimal performance

Online Monitoring and Display Platform

Automation Control System