1.Precise Metering & Automatic Control

Equipped with a high-precision electronic weighing system or variable frequency dosing mechanism, the Fiber Feeding System ensures accurate metering and stable fiber delivery. Fiber Dosing System can be seamlessly integrated with central PLC/DCS control systems for real-time management.

2.Specialized Design for Lightweight and Fluffy Materials

Engineered to handle materials with low bulk densityand high entanglement risk—such as polypropylene fibers and wood fibers—this Fiber Dosing System ensures continuous, smooth operation without clogging or bridging.

3.Anti-Tangling & Anti-Clogging Mechanism

Incorporates an internal screw agitator or fiber dispersion mechanism to effectively prevent fiber clumping and blockages, maintaining consistent flow throughout the dosing process.

4.Compact Structure & Flexible Installation

The modular, space-efficient design allows for flexible installation above batching plants, mixers, or within standalone metering hoppers, making fiber feeding system adaptable to various production layouts.

5.System Integration & Intelligent Control

Fully compatible with automated control systems, supporting remote parameter settings, synchronized operation with other equipment, and fault alarms for enhanced efficiency and safety.

6.Stable Operation & Easy Maintenance

Driven by a variable frequency motor, the Fiber Dosing System ensures low-noise, low-vibration performance. Tool-free access allows quick disassembly and cleaning, ideal for operations requiring frequent fiber type changes.

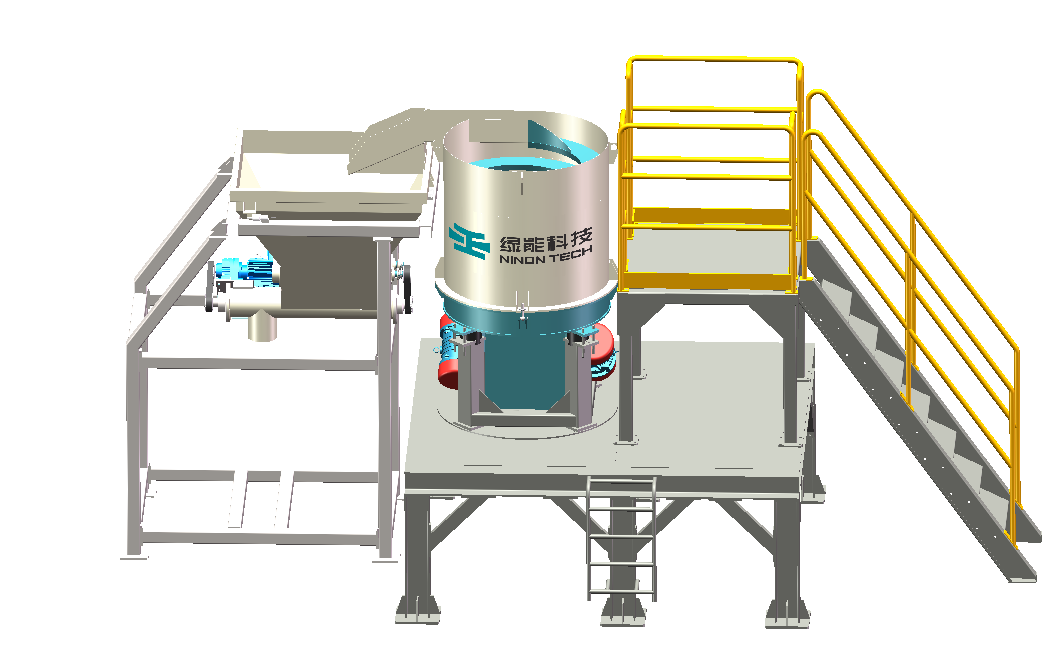

Product Structure

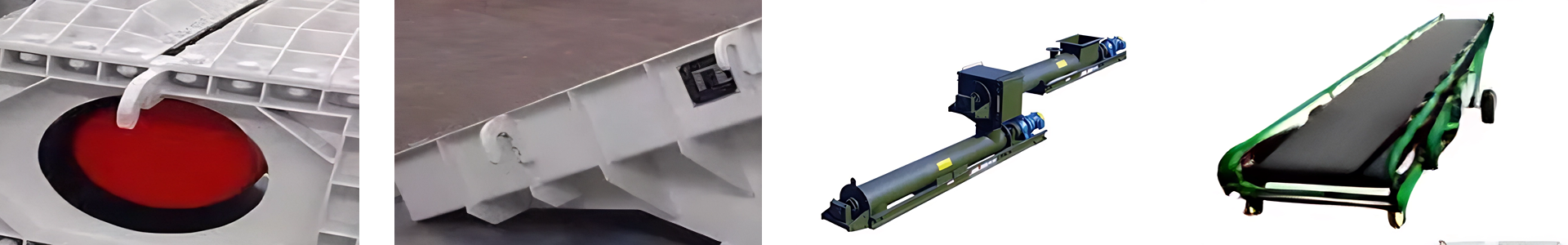

The product structure primarily comprises a screw-type vibrating feeder, a toothed rotary disintegrating unit, a metering screw conveyor, and a belt conveyor.

Specification

| Feeding Capacity | 0.5 -50 kg/h |

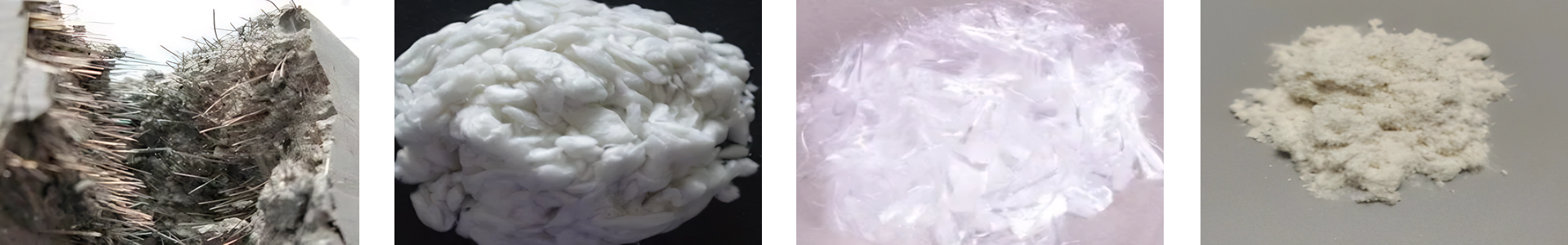

| Applicable Fiber Types | glass fibers, rock wool etc. and other lightweight fibers |

| Weighing Accuracy | ±0.2–0.5% |

| Control Method | PLC or DCS control platforms |

| Discharge Method | screw discharge or air-blowing discharge |

| Motor Type | variable frequency motor |

| Installation Options | modular design, installed above mixers, batching scales or standalone metering stations |

Applicable Material Types

The material types for Fiber Dosing System using are lightweight substances such as steel fiber, glass fiber, polypropylene fiber, wood fiber, basalt, ceramsite shale, and vitrified microbeads.

Range of Configuration