Production Work

The Production Department, based on the specifications provided by the R&D Department according to customer requirements, formulates the production plan, ensuring that all raw materials, components, and tools are fully prepared before production begins to avoid production delays. The required raw materials and components are purchased based on the production plan. These raw materials undergo mechanical processing, such as cutting and drilling, to manufacture various components. Through welding, these parts are assembled into semi-finished products or components.

The components are then manufactured, assembled and tested according to the design drawings to form the basic structure of the product. During the production process, real-time quality monitoring and data recording are carried out to ensure that each step meets the quality standards.

Once production is completed, there is a final inspection to ensure compliance with technical specifications and customer requirements, followed by necessary functional testing. The products are then packaged to protect them during transportation and are labeled and organized according to customer requirements.

The final products are stored in the warehouse, awaiting shipment. Inventory management is conducted to ensure smooth logistics operations. Finally, based on customer orders, shipping arrangements are made to ensure timely and safe delivery of the products to customers.

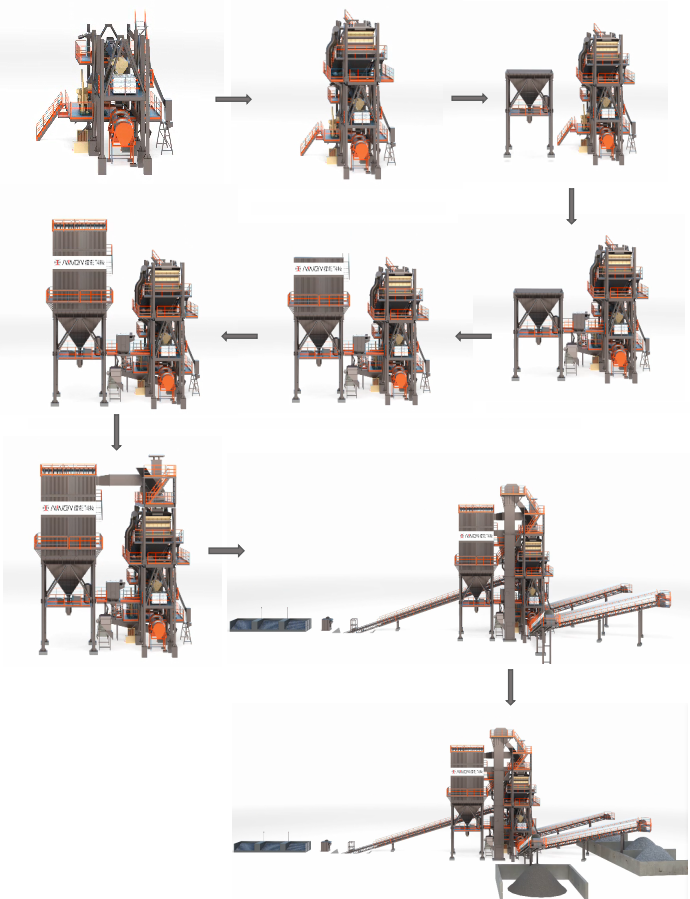

Equipment Installation Process

Ninon follows a standardized and systematic equipment installation process to ensure the safe, efficient, and high-quality installation of all production equipment. The process is carefully designed to minimize site risks, reduce installation time, and ensure that the equipment operates at optimal performance levels from the outset.

1. Pre-installation Preparation

Before installation, our engineering team conducts a detailed site survey and evaluates the installation environment, foundation conditions, and infrastructure readiness. Technical drawings, equipment layout plans, and installation guidelines are reviewed with the client to ensure accuracy and feasibility. Necessary lifting equipment, tools, and auxiliary materials are prepared in advance.

2. Equipment Positioning & Foundation Work

Based on the approved layout plan, precise positioning of each equipment unit is carried out. Foundation work, including concrete pouring, anchor bolt placement, and leveling, is completed according to design standards to ensure structural stability and load-bearing capacity.

3. Equipment Installation & Assembly

Our professional installation team conducts the mechanical assembly, connection of pipelines, power wiring, and necessary structural integrations. Critical components such as vibrating feeders, crushers, classifiers, and conveyors are installed following strict alignment, leveling, and torque requirements to prevent vibration, wear, and premature failure.

4. System Debugging & Testing

After mechanical and electrical installation, a comprehensive system debugging phase is carried out. This includes no-load testing, load testing, and performance tuning. Parameters such as feeding rate, vibration frequency, classification accuracy, and discharge specifications are adjusted to meet project requirements.

5. Safety Inspection & Acceptance

Upon completion, a joint safety inspection and acceptance check are organized involving both our technical team and the customer. All equipment must pass mechanical, electrical, and operational safety evaluations before entering formal production.

6. Training & Handover

We provide on-site training for operators and maintenance personnel to ensure proper equipment use and daily maintenance procedures. Formal documentation and operation manuals are handed over for future reference.

On-site Installation

Semi-finished products and product testing

Semi-finished Products

Product Testing

Finished goods dispaly