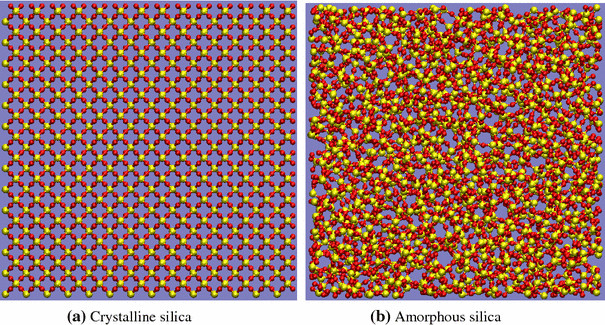

When discussing silica dust, it’s critical to distinguish between crystalline silica (or "free silica") and amorphous silica—two silica forms with drastically different health effects, often confused due to misinformation. Crystalline silica is far more harmful, and its release is closely tied to aggregate processing equipment, which is widely used to crush, screen, or grind natural aggregates like rocks and sand.

Crystalline Silica: The Invisible Killer

Crystalline silica is abundant in rocks, sand, and building materials. When these materials are processed by aggregate processing equipment—such as crushers, grinders, or drill rigs during aggregate production—fine crystalline silica dust is released into the air. These tiny particles easily bypass the respiratory system’s defenses, settling deep in the lungs. Prolonged inhalation causes silicosis (a fibrotic lung disease) and raises risks of respiratory illnesses and lung cancer; the WHO classifies crystalline silica as a human carcinogen.

Amorphous Silica: A Relatively Harmless Companion

In stark contrast to crystalline silica is amorphous silica, which exists primarily in the form of glass in our daily lives. Glass, a seemingly ordinary yet fascinating substance, is produced by heating sand (mainly composed of silica) to a high temperature and then cooling it rapidly. During this process, the silica molecules that might otherwise form crystals are unable to arrange themselves in an orderly manner due to the rapid cooling, resulting in an amorphous structure known as amorphous silica.

Unlike crystalline silica dust, inhaling glass dust does not pose a carcinogenic risk. Of course, long-term and excessive inhalation may still cause certain irritation and damage to the respiratory system, such as triggering asthma and other respiratory issues. Fortunately, however, the human body has a certain self-clearing ability, which can gradually expel the inhaled amorphous silica from the body within a few weeks.

In-depth Differentiation and Scientific Prevention

To protect health, we must target risks from aggregate processing equipment. In workplaces using this equipment, strictly follow safety rules: wear qualified dust masks and goggles to reduce inhalation. For processes like crushing or grinding that generate crystalline silica dust, use wet work or ventilation to lower dust levels. Also, strengthen occupational health monitoring for workers operating aggregate processing equipment, and provide education on silica risks.

In summary, crystalline and amorphous silica differ sharply in health impacts. Addressing risks from aggregate processing equipment—through safe use and prevention—is key to shielding against silica dust harm.