Still struggling with site challenges? Want to install a dry-mix mortar production line but held back by limited space, awkward shape, or existing facilities?

Don’t worry! Ninon's Dry-Mix Mortar Production Line comes with built-in site customization capabilities — turning your production site from a hassle into a non-issue!

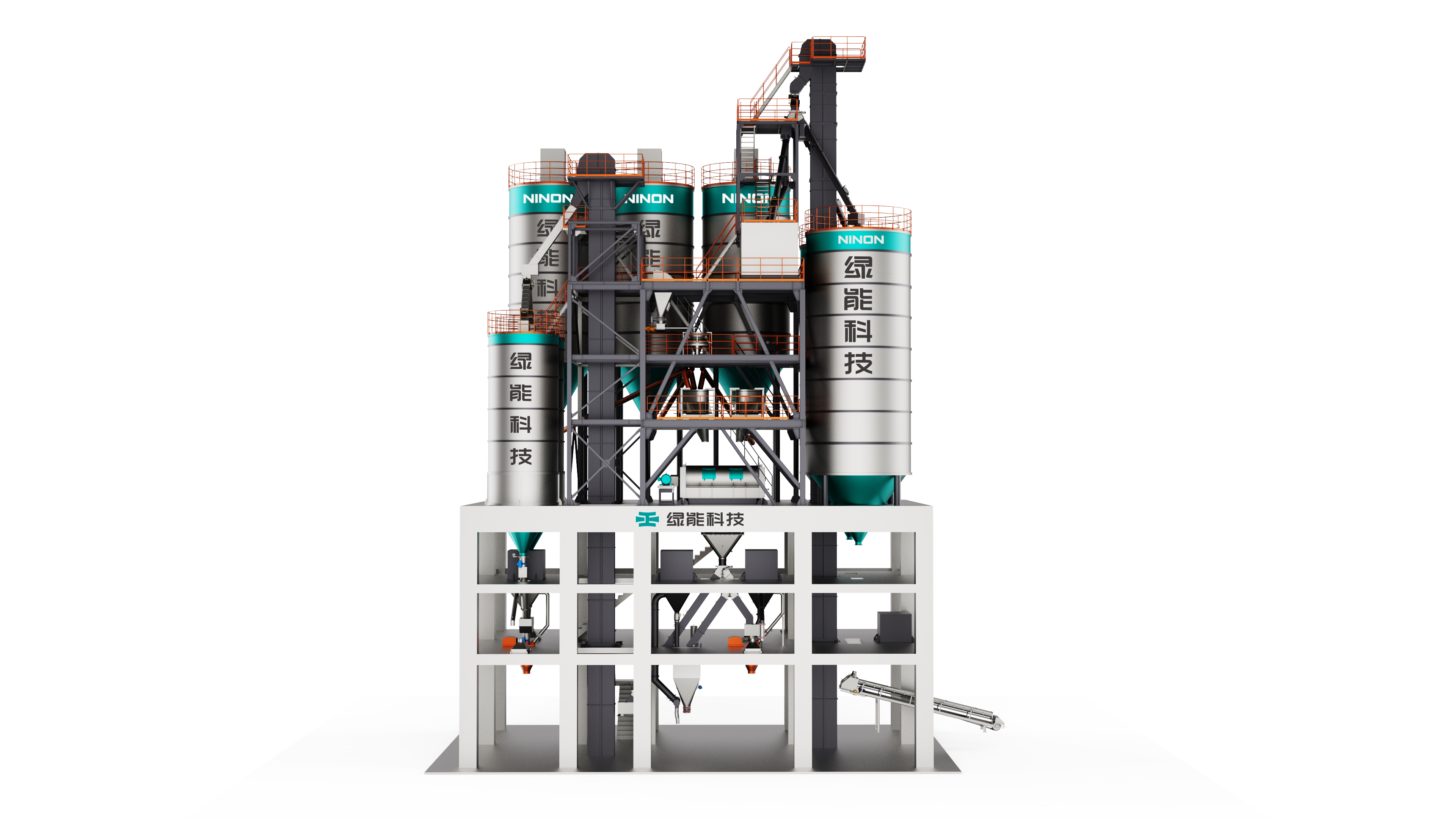

Modular Design, Customer-Tailored Services

Whether your site is narrow and long, irregular-shaped, or dotted with obstacles like columns and load-bearing walls, Ninon can provide tailor-made solutions for your dry-mixed mortar plant based on the actual situation.

The dry-mixed mortar production line adopts a modular design, where each functional unit of the ready mixed mortar plant can be flexibly combined just like Lego bricks.

◆ Want to save space for your dry-mixed mortar plant?

The ready mixed mortar plant can be designed into a multi-layer three-dimensional layout to fully utilize vertical space, making the dry-mixed mortar production line highly space-efficient.

◆ Dealing with a special-shaped site?

Simply split the units of the dry-mixed mortar production line and arrange them in a staggered manner to avoid obstacles, ensuring operates smoothly.

◆ Need to integrate old equipment into your dry-mixed mortar plant?

No problem — the dry-mixed mortar production line is equipped with reserved interfaces that enable seamless connection between new and old components of the ready mixed mortar plant.

Site-Tailored Dry-Mixed Mortar Plant—— No Compromise on Production Efficiency

Don't assume that site-specific customization for your dry-mixed mortar production line or ready mixed mortar plant compromises production efficiency; on the contrary, Ninon's customized design for the dry-mixed mortar plant makes production more streamlined. It reasonably plans raw material transportation routes for the dry-mixed mortar production line based on on-site logistics, reducing material handling distance for the ready mixed mortar plant. Operating platforms of the dry-mixed mortar plant are arranged in line with operators' working habits to lower labor intensity, further optimizing the dry-mixed mortar production line's operational efficiency. Even equipment maintenance access for the ready mixed mortar plant is taken into account, facilitating post-operation maintenance of the dry-mixed mortar plant.

Complemented by the high-performance modular formula management system of the dry-mixed mortar production line, it enables one-click product type switching and rapid adjustment of formulas and processes. Whether it's common masonry mortar, plastering mortar, or special-requirement thermal insulation mortar and anti-crack mortar, the dry mixed mortar production line can produce all efficiently, proving the versatility.

Facing site challenges for your dry-mixed mortar plant? Looking to invest in a high-quality ready mixed mortar plant? Don’t hesitate to contact Ninon, and let our professional team create tailor-made solutions for your dry-mixed mortar plant, ensuring your ready mixed mortar plant delivers exceptional performance and efficiency!