Compared with the construction of new expressways, the reconstruction and expansion of existing expressways requires renovation of the original pavement, which will inevitably generate a large amount of construction waste such as asphalt pavement millings. Random stockpiling or disposal of such waste not only occupies land resources but also causes environmental pollution; meanwhile, it leads to severe waste of stone and asphalt resources contained in the waste. To realize the resource utilization of asphalt waste and turn "waste" into "treasure", the relevant technologies and professional equipment in the asphalt recycling field are the core keys.

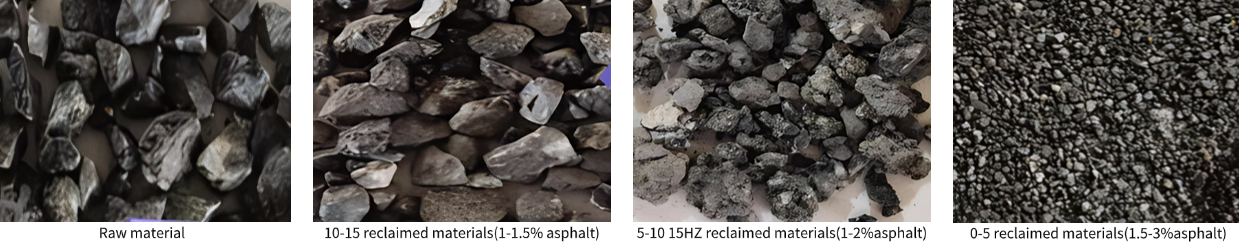

The key to solving the problem of realizing the "waste-to-treasure" application of asphalt waste lies in ensuring that these recycled materials can meet the performance standards of raw materials. Currently, in the market, the coarse aggregates and fine aggregates formed after milling asphalt mixtures, even after conventional secondary crushing and screening, still contain an excessive amount of "false" large particles, leading to high variability and unstable gradation when used in high-proportion recycling. As a result, the mixing amount of RAP (Reclaimed Asphalt Pavement) materials cannot be increased during the application process.

Process Design and Compoent Composition of RAP Asphalt Recycling Equipment

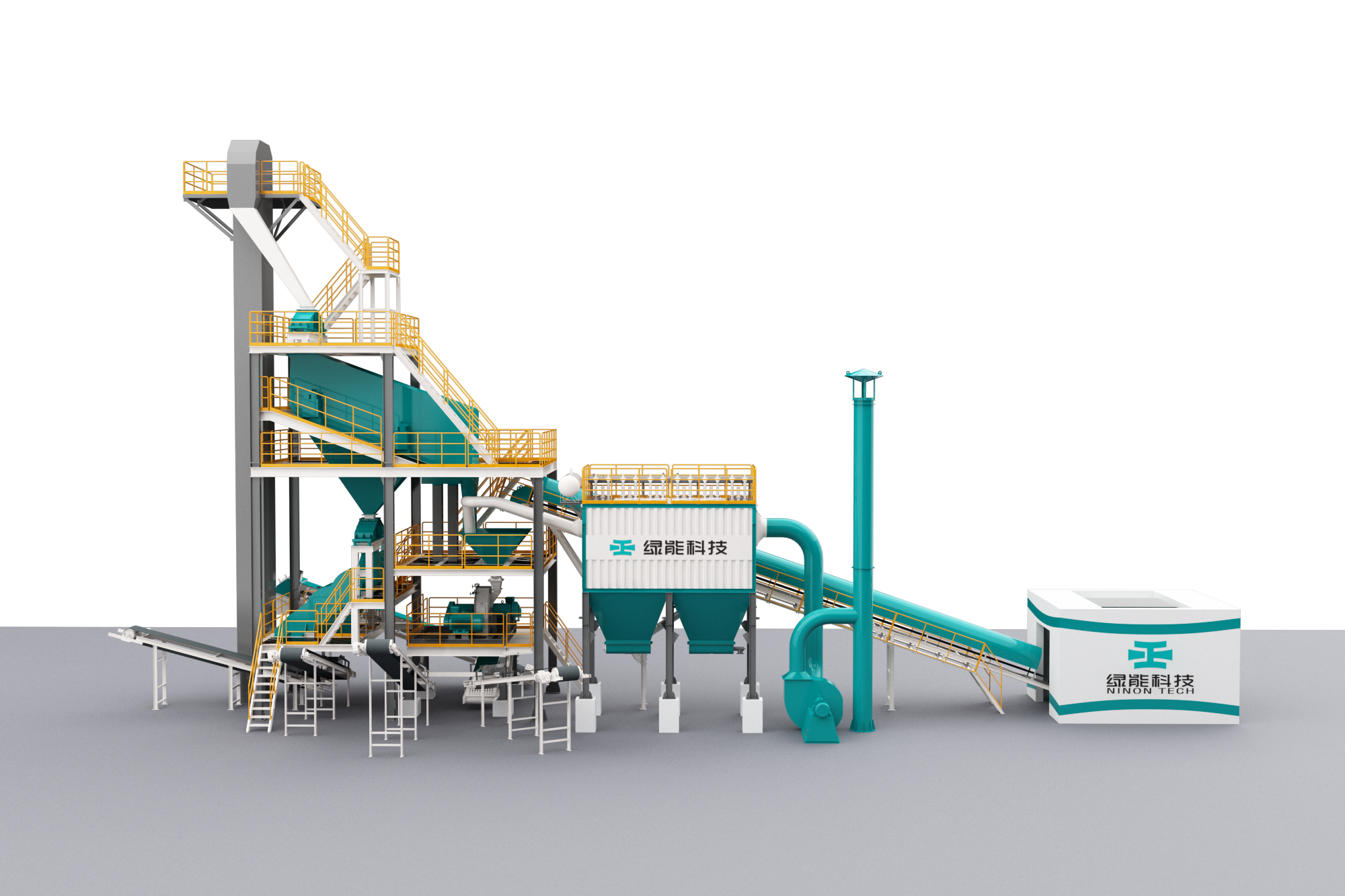

Specifically, the RAP asphalt aggregate recycling equipment at the heart of road construction and building materials factories features a variety of process designs tailored to the source properties of RAP and processing requirements. For instance, the simple processing scheme within the asphalt recycling plant mainly adopts the mode of "screening first and then stripping" or "stripping first and then classification"—a flexibility made possible by the modular design of the RAP asphalt aggregate recycling equipment. The target finished products of this integrated system are 2-3 grades of materials, which are generally used in the lower base course or stabilization course of expressways, municipal engineering projects, etc. To deliver this performance, the asphalt recycling plant (and its core RAP asphalt aggregate recycling equipment) is composed of key components: a raw material silo, an oversize material removal device, an iron remover for the material distribution system, a conveying system, a stripping machine, a screening machine, a dust removal system, and an intelligent control system. Each component works in tandem with the RAP asphalt aggregate recycling equipment to optimize efficiency and product quality.

After the raw material stripping process in the asphalt recycling plant, the screening, pre-screening, stripping, and fine screening modules of the RAP asphalt aggregate recycling equipment can be designed into either a horizontal layout or a tower-type structure—adapting to different site conditions and production scales. The core unit of this RAP asphalt aggregate recycling equipment (and thus the asphalt recycling plant) is the RAP Kneading and Depolymerizing Machine (also known as the HCC Grinder), an industry-first innovation. This unit integrates multiple technologies—primarily shearing and kneading, supplemented by moderate flexible impact—to perform composite processing on recycled materials, effectively removing asphalt and minimizing over-crushing. To cater to diverse RAP characteristics, the processing parameters of the RAP asphalt aggregate recycling plant can be adjusted through various means, including modifying the frequency, the spacing between kneading rods, the shape of the rods (square, hexagonal, prismatic, or comb-toothed), the material and diameter of the rods, and the number of cages (ranging from 2 to 6). Such adjustability ensures the asphalt recycling plant can handle RAP from different sources while maintaining high product standards.

Multi-Scenario Utilization of Recycled RAP