Project Overview

Hunan Liuyang Machang Building Materials Co., Ltd. focuses on sand and gravel processing, as well as concrete and dry-mixed mortar sales. In 2018, it launched a key manufactured sand project promoted by Hehua Sub-district, building a new dry-type manufactured sand production line at the former Liuyang Ximei Fireworks Factory (Machang Group, Nanhuan Village). This manufactured sand production line achieves an annual output of 250,000 tons of manufactured sand, 100,000 tons of dry-mixed mortar, and 10,000 tons of mineral powder. Covering 18,262 square meters with a total investment of 20 million yuan (including 220,000 yuan for environmental protection).

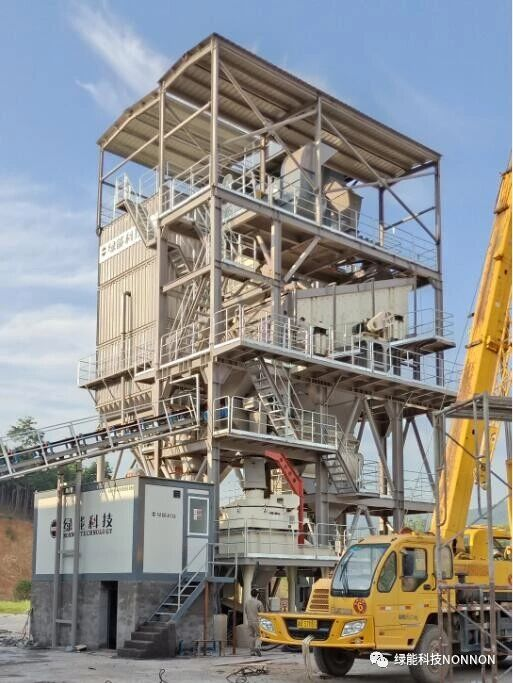

The sand making machine from the project of Liuyang Machang Building Materials is produced by Ninon, and has successfully passed the environmental impact assessment of Liuyang Environmental Protection Bureau. In addition, the manufactured sand of Machang Building Materials can replace river sand, filling the gap of river sand shortage in Liuyang's construction market and contributing to river protection. This project is a typical case of Hehua Sub-district's promotion of project construction and introduction of social investment.

On August 1, 2018, the project’s Ninon-manufactured DS100 eco-friendly manufactured sand production line was put into operation. Liuyang Daily reported: “Tailings enter the line via conveyors, and fine manufactured sand flows out minutes later—no dust or odd odors.” This reflects the line’s full environmental protection, green, and intelligent features.

Technical Highlights

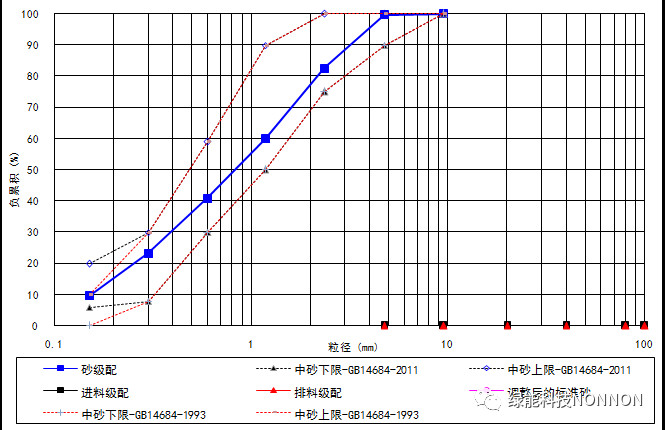

Ninon’s DS sand-making tower (core of the manufactured sand production line) pioneers a dual-host mode: main crusher + high-speed grader. It supports single/mixed dual-machine production, adapting to 5-40mm material grading or independent 2-16mm raw material processing. This solves sand gradation issues, handles small hard rock crushing, and processes 5-40mm single/multi-graded raw materials (overcoming single-host limitations). It enables online sand gradation adjustment (no screen replacement/shutdown) and alternate host operation during maintenance, boosting utilization. The system uses eddy current powder selection and a particle recoverer, adjusting stone powder content (4%-15%) and meeting 20mg/m³ emission standards.

Appearance of Manufactured Sand Products

Conlusion

Liuyang Machang’s project, with Ninon’s advanced manufactured sand production line, eases local sand shortage, meets eco-standards, and sets a model. The line’s dual-host design and eco-features also showcase its value for green sand industry development.