Limestone is the top raw material for high-quality manufactured sand, but a profitable manufactured sand production line depends entirely on smart aggregate processing equipment selection. For global buyers aiming to meet standards like ASTM C33 or EN 12620, here’s how to pick the right gear—with a focus on the sand making machine, core of any limestone line.

Primary Crusher: Star with Aggregate Processing Equipment that Matches Capacity

The first step in building a limestone manufactured sand production line is choosing a primary crusher—foundational aggregate processing equipment. Limestone’s brittleness favors jaw or impact crushers:

For large feed (500–1000mm, 100–500 TPH): A jaw crusher works best. It fits seamlessly into high-capacity sand making plant, handling boulders common in Brazil or India, with a 6:1–8:1 crushing ratio.

For medium feed (200–500mm, 50–150 TPH): An impact crusher is better. It cuts secondary processing work for your sand making plant—used it to boost efficiency by 30%. Avoid cone crushers; they’re overpriced for limestone and waste aggregate processing machinery budget.

Sand Making Machine: The Hearts of Your Manufactured Sand Production Line

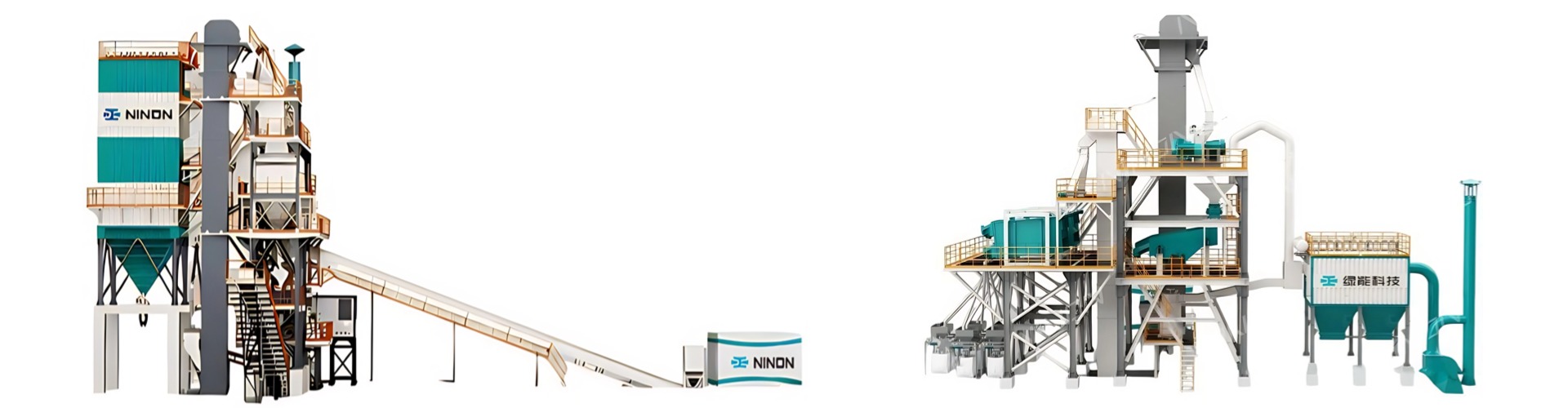

To get cubical, uniform sand (elongation ≤15%), the sand making machine is non-negotiable in aggregate processing machinery. For limestone: Use a VSI crusher (core sand making machine) for tertiary crushing. Pair with an impact crusher (secondary) for 10–20mm particles. Ninon's machinery let you adjust shape, perfect for sand making plant serving roads and high-rises. Skip hammer crushers; they ruin sand quality and your manufactured sand production line’s reputation.

Screening & Washing: Essential Aggregate Processing Equipment for Purity

Limestone’s clay/silt ruins sand quality—so add these to your sand making machine: Vibrating screens: Multi-layered aggregate processing equipment that sorts sand into 0–3mm/3–5mm grades. Waterproof meshes keep humid-region sand making machine running. Sand washers: This aggregate processing equipment cleans impurities, with water recycling cutting use by 40%. Dry regions can use dust collectors to meet EU standards.

Auxiliaries & Support: Keep Your Manufactured Sand Production Line Running

Don’t overlook auxiliary aggregate processing equipment:

Corrosion-resistant conveyors prevent rust in coastal cities, matching feed to the sand making machine. PLC controls monitor all aggregate processing equipment, cutting downtime by 40% for a construction material manufacturer.

Choose suppliers like Ninon with global service—local parts (sand making machine rotors, crusher jaws) deliver in 48 hours, and they handle CE/ISO/CSA certifications for your manufactured sand production line.

Conclusion

A successful limestone manufactured sand production line relies on matching aggregate processing machinery to your needs: jaw/impact crushers for primary work, a VSI sand making machine for quality, and smart auxiliaries for efficiency. With the right gear, your machine-made sand production line becomes a profitable, compliant asset—no matter your global market.