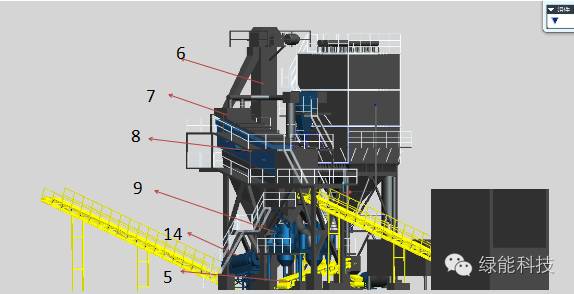

Ninon’s Environmental-Friendly Tower-Type sand making plant has become a core driving force for the green transformation of modern sand making plants, addressing industry pain points like high pollution, high water consumption, and large space occupation with innovative design. As a integrated sand making machine, it combines four key processes—raw material crushing, particle screening, powder separation, and dust collection—into a vertical tower structure, which means a sand making plant no longer needs to arrange scattered equipment, greatly reducing the plant’s floor area by 40% compared to traditional layouts. This is especially valuable for sand making plants in urban suburbs or mountainous areas where land resources are tight, helping them make full use of limited space to expand production.

What makes this sand making machine truly "environmental-friendly" is its dry-process production mode: it completely abandons the water-dependent operation of traditional wet sand making machines, so a sand making plant doesn’t need to build water intake pipelines or wastewater treatment pools. This not only saves tens of thousands of tons of water resources for a sand making plant every year (critical for arid northern regions) but also avoids the problem of water pollution caused by wet-process wastewater discharge—helping the sand making plant easily pass environmental protection inspections. Additionally, the sand making machine is equipped with a high-negative-pressure dust collector, which captures over 98% of the dust generated during crushing and screening, ensuring the sand making plant ’s workshop and surrounding environment meet national air quality standards.

In terms of production performance, this sand making machine excels at processing high-hardness raw materials like cobblestones, granite, and basalt, converting them into high-quality manufactured sand with uniform particle size (85% of particles meet 0-5mm specifications) and good cubical shape—fully meeting the requirements of high-grade concrete and mortar. For a sand making plant, the stable output of this sand making machine ensures continuous supply to construction projects, enhancing the plant’s reputation among clients. Moreover, the sand making machine’s key components are made of wear-resistant alloy materials, extending their service life by 50% and reducing the frequency of part replacements for the sand making plant—lowering maintenance costs significantly.

In summary, Ninon’s Environmental-Friendly Tower-Type Sand Making Machine is not just a piece of production equipment, but a comprehensive solution that helps sand making plants achieve green operations, improve efficiency, and cut costs—becoming an indispensable choice for sand making plants pursuing sustainable development.