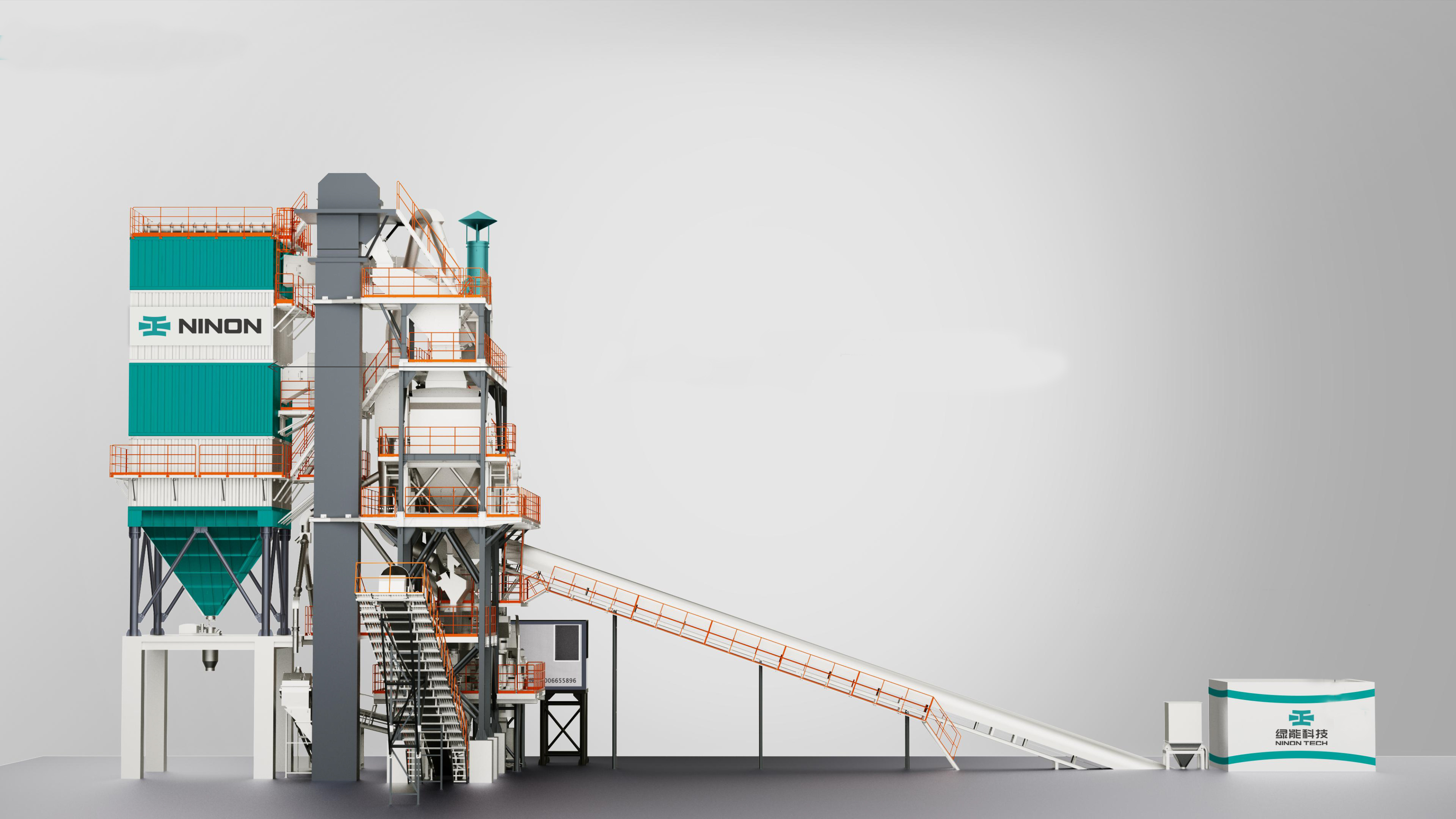

In the raw material supply of commercial concrete, dry-mixed mortar and other construction fields, the stable output of high-quality manufactured sand is a key guarantee for project quality and efficiency. Ninon's 150 T/H aggregate shaping and sand making equipment, a core component of advanced manufactured sand production lines, is tailored specifically for limestone raw materials. Owing to its tower-type structure, intelligent control system and practically verified reliability, it has become the preferred sand making machine for manufactured sand needs in the construction industry, outperforming many traditional sand making machines in integration and stability.

Ninon's aggregate shaping and sand making equipment adopts a tower-type integrated design—an innovative layout that sets it apart from conventional sand making machines. It features a compact and reasonable structure that significantly saves floor space, a critical advantage for enterprises looking to optimize their manufactured sand production line layout. Meanwhile, it simplifies the installation process of the entire system, enabling the manufactured sand production line to quickly put into production.

This tower-type sand making equipment is suitable for limestone raw materials with a particle size of 5-31.5mm; through precise shaping and sand-making technology, it can stably produce dry sand finished products with a fineness modulus between 2.3-3.2. The finished sand has a round and full particle shape and a continuous and reasonable gradation, fully meeting the production requirements of high-end building materials such as commercial concrete and dry-mixed mortar, and effectively improving the strength and durability of end products—an outcome that many ordinary sand making machines struggle to achieve consistently.

High efficiency and stability are the core competitiveness of this sand making machine, a key highlight that makes it a game-changer for manufactured sand production lines. Unlike outdated sand making equipment prone to performance fluctuations, this sand making machine can achieve continuous and stable production of 150 T/H, completely solving the pain point of large production capacity fluctuations of traditional sand making machines. It provides continuous raw material supply for large-scale engineering construction, ensuring that the manufactured sand production line operates without interruptions. More notably, the equipment has been put into operation for more than a year, with a cumulative trouble-free operation time exceeding 2600 hours—equivalent to stable daily operation of more than 7 hours. Such practical data fully verifies the excellent reliability and durability of this sand making equipment, greatly reducing the maintenance costs of the manufactured sand production line and the losses caused by sand making machine downtime.

Production Site

The sand making equipment is equipped with a full set of intelligent control systems, which can real-time monitor the entire production process of the manufactured sand production line—including crushing, shaping and screening—with key operating parameters of the sand making machine clearly visible at a glance. Operators can achieve remote regulation of the sand making equipment through the central control system, responding promptly to changes in raw materials and adjustments in production capacity requirements. This not only reduces the manufactured sand production line’s reliance on manual labor but also improves the production accuracy of the sand making machine, ensuring that the quality of finished sand consistently meets standards—a level of precision that traditional sand making equipment rarely attains.

intelligent control system

Whether it is large commercial concrete mixing stations, dry-mixed mortar production enterprises, or large-scale sand and gravel aggregate plants, this 150 T/H shaping sand-making tower will be a pivotal addition to their manufactured sand production lines. Relying on its high-efficiency production capacity (surpassing many standard sand making machines), high-quality finished products and reliable performance, this sand making equipment provides strong support for enterprises to reduce costs and increase efficiency. Choosing this sand making machine—verified by practical operations—means choosing a stable guarantee for the manufactured sand production line’s output, project quality and the sustained growth of enterprise benefits.