Brief Introduction

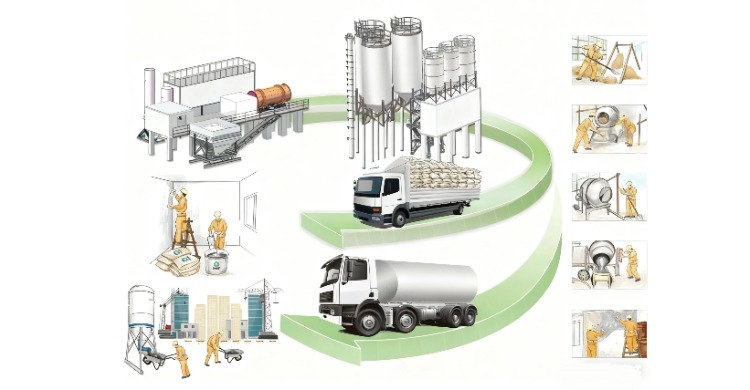

Dry-mixed mortar (also known as dry powder mortar) is a kind of "dry-mixed" ready-mix commercial mortar produced industrially by advanced production equipment—microcomputer-controlled fully automatic dry-mixed mortar mixing stations (towers). The production process includes sand pre-treatment (including drying and sieving), batching and metering, mixing, storage and packaging, or bulk delivery. Thanks to the strict weighing and proportioning during production, as well as the addition of corresponding chemical additives according to the different functional requirements of the mortar, the quality of the mortar is greatly improved. The application of dry-mixed mortar avoids the quality defects caused by on-site manual preparation, ensures the quality of construction work, and at the same time reduces urban waste and environmental pollution.

Production Process of Dry-mixed Mortar

1. Sand pre-treatment includes quarrying, crushing, drying, (grinding), sieving, and storage. For river sand, only drying and sieving are required; where conditions permit, finished sand can be directly purchased and sent to the sand silo.

2. Binders, fillers, and additives are delivered to their respective silos.

3. Batching and metering are carried out according to the formula.

4. Various raw materials are put into the mixer for stirring and mixing.

5. The finished mortar is sent to the finished product silo for packaging or bulk storage.

6. The products are transported to the construction site. Bulk dry-mixed mortar must be transported by bulk silos or special bulk transport vehicles to prevent segregation, which may affect the quality of construction work.

7. The dry-mixed mortar is put into a mortar mixer and mixed with water in proportion.

8. A special mortar pump is used to transport the mixed mortar to the construction site or directly perform on-site shotcreting construction.

Ready Mixed Mortar Production Line

A dry mixed mortar plant is a integrated facility designed for centralized blending of ordinary and special mortars, often serving as the core of a ready mixed mortar production line. Both the dry mixed mortar plant and ready mixed mortar production line come in diverse types, classified based on key characteristics:

By mixing method: Single-mix and double-mix variants, which are widely adopted in both standard dry mixed mortar plants and customized ready mixed mortar production lines.

By structural form: Simple, serial, and tower-type designs, each tailored to different scales of dry mixed mortar plants and the operational needs of ready mixed mortar production lines.

These dry mixed mortar plants boast flexible structural configurations, strong adaptability, and modular expandability. Their control modes range from manual to semi-automatic and fully automatic; dry sand processing relies on vibrating fluidized beds or mechanical drums; mixing hosts include gravity-free double-shaft paddle mixers, horizontal ribbon mixers, and plow-type mixers, available in batch or continuous operation to suit the workflow of dry mixed mortar production lines.

The core components of a dry mixed mortar production line include: sand pre-treatment (drying, sieving, conveying) systems, powdery material storage systems, batching and metering systems, mixing systems, packaging and bulk systems, dust collection systems, electrical control systems, as well as logistics transportation and on-site mixing-spraying equipment.

1. Sand Pre-treatment System

As the foundational step for dry mixed mortar plants, sand accounts for 70% of dry mixed mortar composition. Raw sand must undergo moisture testing, drying, sieving, and conveying to maintain 0.2%-0.5% moisture content, ensuring the stability of finished products stored in airtight silos within the dry mixed mortar plant.

2. Material Storage System

A dry mixed mortar plant requires dedicated silos for aggregates (dry sand), cementitious materials (cement, gypsum powder), admixtures, and chemical additives, supporting precise ingredient management throughout the production cycle.

3. Batching and Metering System

Critical to the quality of outputs from ready mixed mortar production lines, this system relies on high-precision equipment and advanced automation to guarantee accurate formula execution, a non-negotiable standard for reliable production.

4. Mixing System

The heart of any dry mixed mortar plant, it ensures uniform distribution of cementitious materials, admixtures, and additives on aggregate surfaces, directly determining the quality of the final product.

5. Packaging and Bulk System

Finished mortars are either packaged via automatic machines or stored in special bulk silos for transport, a process seamlessly integrated into the ready mixed mortar production line’s end-to-end workflow.

6. Dust Collection System

Essential for maintaining safe working conditions in dry mixed mortar plants, cyclone dust collectors and bag filters are deployed to handle dust generated during pneumatic conveying and mixing processes.

7. Electrical Control System

Equipped with PLC and PC control, it oversees the entire operation of the dry mixed mortar production line, including formula management, data logging, and networked monitoring, enabling intelligent production oversight.

8. Logistics Transportation

Bagged mortars from the dry mixed mortar plant are shipped via standard trucks, while bulk products require specialized silos or tankers to prevent segregation— a critical step in preserving the integrity of materials from the ready mixed mortar production line to the construction site.

9. Mixing and Spraying Construction Equipment

Mechanized tools enhance the application of mortars produced by the dry mixed mortar plant, improving uniformity, ensuring construction quality, and boosting overall efficiency with advanced technological support.