Currently, with the rising demand for mine stone materials across regions, more mine enterprise owners are expanding production scales to boost output. Thus, selecting a suitable complete set of manufactured sand production lines has become a critical task. But how to build a successful manufactured sand production line?

A high-quality manufactured sand production line requires excellence in five core aspects. For safety, rational site planning is essential—reserving safe spaces for equipment maintenance, installing hoisting devices above key machinery like the sand making machine and VSI crusher, designing maintenance access, and setting up walkways in belt galleries. Environmentally, adopt closed-circuit water circulation and sewage treatment systems for zero discharge, equip all dust points with high-efficiency dust removal facilities, and harden internal roads. High automation is achieved via programming control, enabling the sand making machine to operate autonomously with automatic fault diagnosis and alarms. Convenient maintenance relies on dedicated spare parts inventories and maintenance centers. Energy conservation involves using energy-efficient equipment, applying frequency conversion for parameter adjustment, and locating substations near load centers.

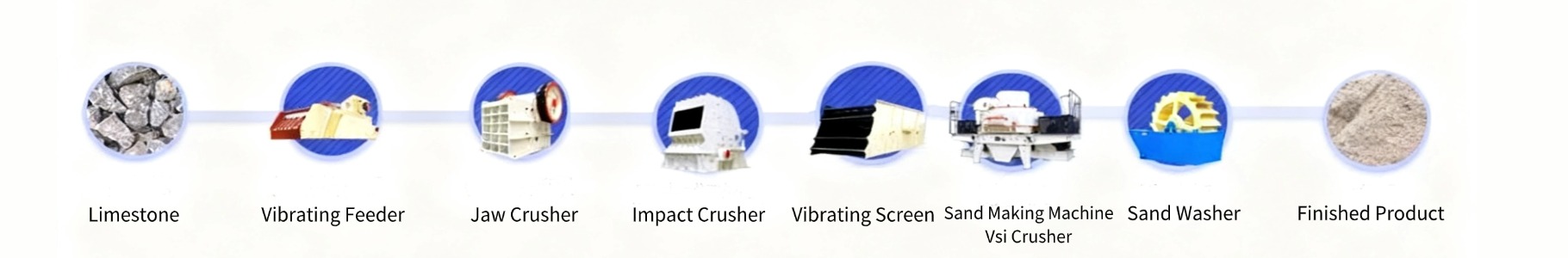

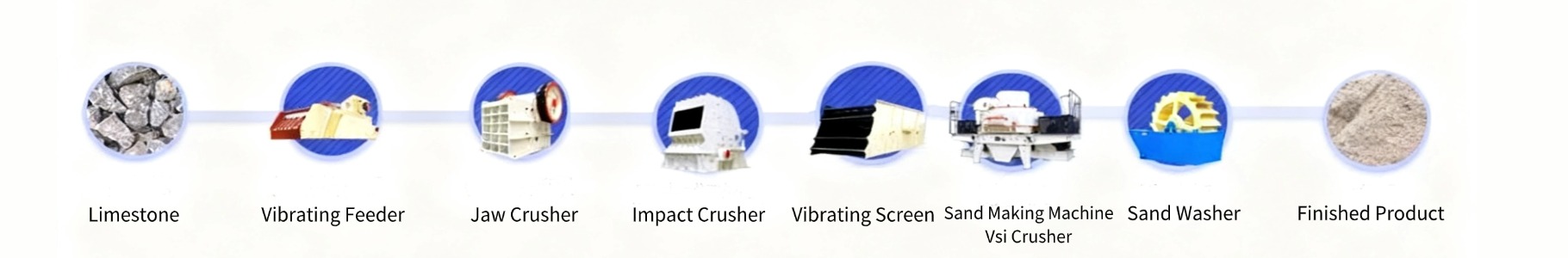

For soft, low-abrasive materials like limestone, the manufactured sand production line features a simple configuration. First, clarify raw material properties (size, hardness, humidity) and output/particle requirements—this guides equipment selection. For example, using a cone crusher for soft rocks increases costs, while a VSI crusher is ideal for shaping. The process includes feeding, crushing, screening, and conveying: raw materials from silos go to vibrating feeders, then primary crushers for rough crushing, followed by secondary crushers. Screened via circular vibrating screens, oversize materials are recrushed, and qualified ones become finished products. Adding a VSI crusher enhances particle roundness.

For hard, high-abrasive materials like granite, the manufactured sand production line leverages the VSI crusher’s laminated crushing principle. After two-stage cone crushing, coarse aggregates enter the VSI crusher for refinement. Key equipment includes jaw crushers (first-stage, handling ≤320MPa materials to 100-300mm), impact crushers (second-stage, handling ≤500mm, 350MPa materials into cubic particles), and the VSI crusher—critical for the sand making machine, suitable for soft to extremely hard materials with 30-60mm feed size. The sand making machine, often a VSI crusher variant, serves as the final shaping stage.

Configuration steps for hard rock manufactured sand production lines: Large materials go from silos to vibrating feeders, then jaw crushers for rough crushing. Screened materials are sent to cone crushers for medium-fine crushing, then circular vibrating screens—oversize materials return to cone crushers. Qualified materials enter the VSI crusher for sand making and shaping; a sand washer can be added for cleaning. Finally, products are classified by particle size.

Notes: The manufactured sand production line’s configuration depends on stone specifications, output, applications, and site conditions. The sand making machine and VSI crusher have diverse models with varying capacities and feed/discharge sizes. Selecting the right VSI crusher and sand making machine for specific needs ensures a reasonable, economical manufactured sand production line.