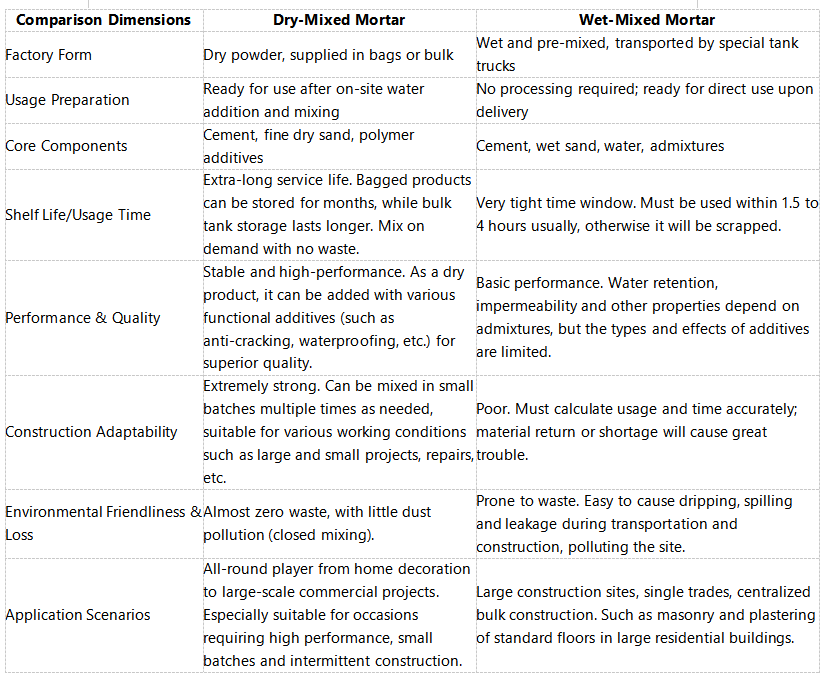

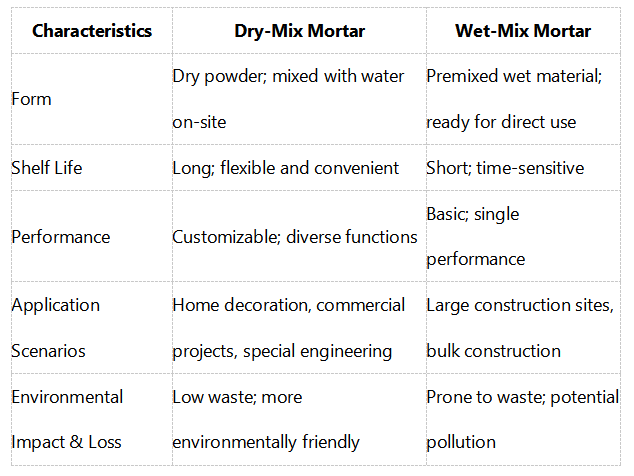

All-Round Comparison: Grasp the Distinctions in One Chart

Way to Choose the Right Mortar

Now that you understand the differences, the choice becomes straightforward. Just ask yourself the following questions:

Q1: What is the scale of the project, and what is the construction rhythm?

(1) If your answer is: Small project scale, discontinuous construction, need for random work stoppages or repairs (e.g., home decoration, villas, small shops, sporadic projects).

✅ Recommendation: Dry-Mixed Mortar

Reason: You can’t use all the mortar in one day for home decoration. Dry-Mixed Mortar allows you to use a few bags today and a few more tomorrow, perfectly matching the decoration rhythm and avoiding significant waste.

(2) If your answer is: Large project scale, concentrated construction, mechanized spraying (e.g., masonry and plastering of standard floors in entire high-rise residential buildings).

■ Consider: Wet-Mixed Mortar

Reason: When dozens of workers operate on the same floor simultaneously, Wet-Mixed Mortar delivered by a single truck can be used intensively within the specified time. It may have cost advantages for bulk purchases.

Q 2: Do I have special requirements for mortar performance?

(1) If your answer is: Yes (e.g., high adhesion required for tile installation, waterproofing for bathrooms, crack resistance for floor leveling).

✅ Highly Recommend: Dry-Mixed Mortar

Reason: Dry-Mixed Mortar has specialized formulas, such as tile adhesive, waterproof mortar, and self-leveling cement—functions that Wet-Mixed Mortar cannot achieve. Its performance far exceeds that of traditional on-site mixed cement mortar.

(2) If your answer is: No, just for basic masonry and plastering.

Either option works, but the final choice should align with your answer to Q 1.

Q 3: Do I care about the construction site environment and material loss?

(1) If you hope for: A clean and tidy construction site, low material loss, and standardized management.

✅ Recommendation: Dry-Mixed Mortar

Reason: Packaged or bulk Dry-Mixed Mortar occupies little space, produces no wastewater discharge, and is mixed in closed equipment (ready mixed mortar plant)—making it a representative of modern civilized construction.

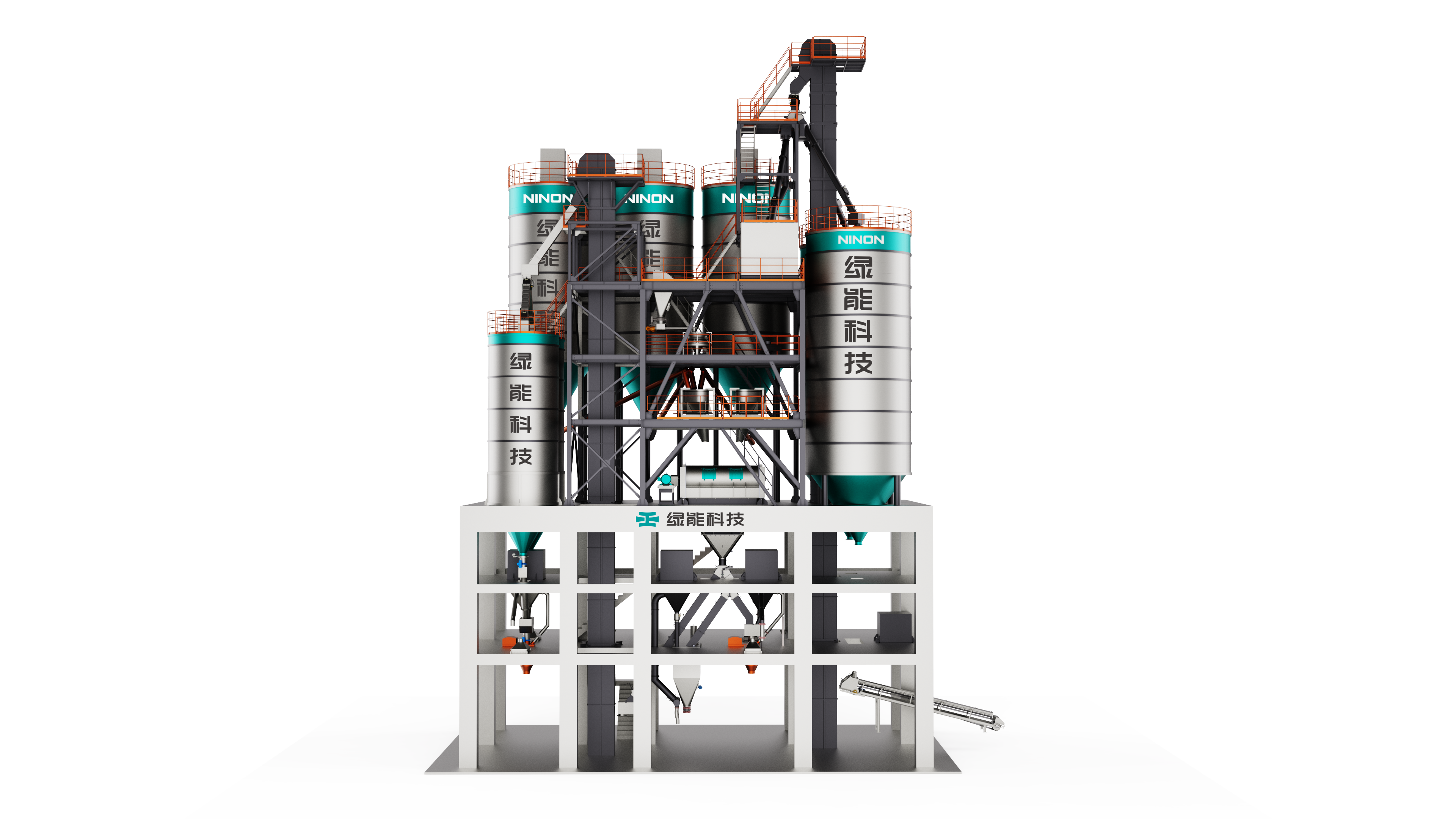

Professional Dry Mixed Mortar Plant for Efficient Construction

A professional dry mixed mortar plant is a game-changer for efficient construction, outperforming a wet mixed morar in flexibility and waste reduction. Unlike a ready mixed mortar plant that delivers time-sensitive wet mortar (prone to spoilage if unused quickly), a dry mixed mortar plant produces pre-blended dry mortar—storable for months, matching varied construction paces.

At the core of a dry mixed mortar plant lies advanced pre-mixed mortar equipment. This pre-mixed mortar equipment ensures precise dosing of cement, sand, and additives, making mortar quality far more consistent than basic setups. In contrast, a ready mixed mortar plant can hanlde the struggle with uniformity, and increase the ready mixed mortar plant’s precision.

For small projects or intermittent work, a ready mixed mortar plant avoids the rush of tight usage windows. Its pre-mixed mortar equipment also cuts on-site dust, aligning with green building. In short, a dry mixed mortar plant—backed by quality pre-mixed mortar equipment—is more suitable for efficient, cost-saving construction.