In the field of Reclaimed Asphalt Pavement (RAP) recycling, "incomplete disaggregation, uneven crushing, and poor quality of reclaimed materials" have long been industry pain points. However, the combination of RAP attrition disaggregator (aggregate crushing machine) and cage crusher is breaking through these bottlenecks with robust capabilities, enabling high-efficiency recycling of old asphalt mixtures and becoming a key tool for engineering companies to reduce costs and improve efficiency.

HCC Aggregate Grinding Mill (Cage Crusher)

RAP Attrition Disaggregator: Precise Disaggregation, Restoring Original Properties

The core of RAP disaggregation lies in "disperse without breaking," and this aggregate grinding mill—accomplishes this flawlessly.

◆ Adopting flexible attrition technology, the cage crusher can thoroughly strips the aged asphalt film from the surface of old materials without compromising the aggregate particle shape, thus guaranteeing stable gradation of reclaimed materials.

◆This aggregate crushing machine boasts exceptional processing efficiency that far outperforms traditional equipment, effectively shortening the construction cycle.

◆Engineered for low-temperature disaggregation, the aggregate grinding mill reduces energy consumption while preventing asphalt thermal aging, resulting in reclaimed materials whose performance is remarkably close to that of new materials.

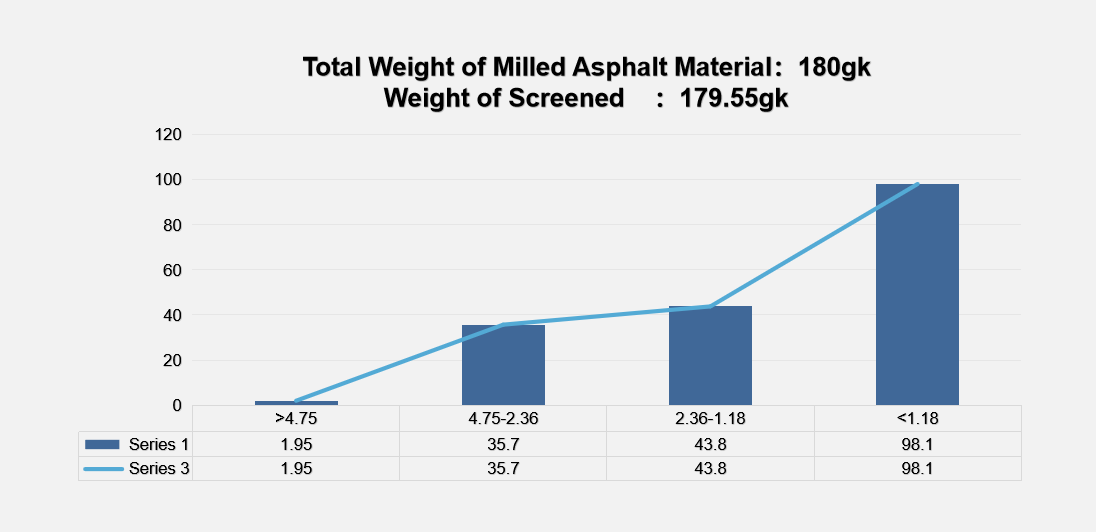

Aggregate Sample of Milled Asphalt Material after Processing by the Cage Crusher

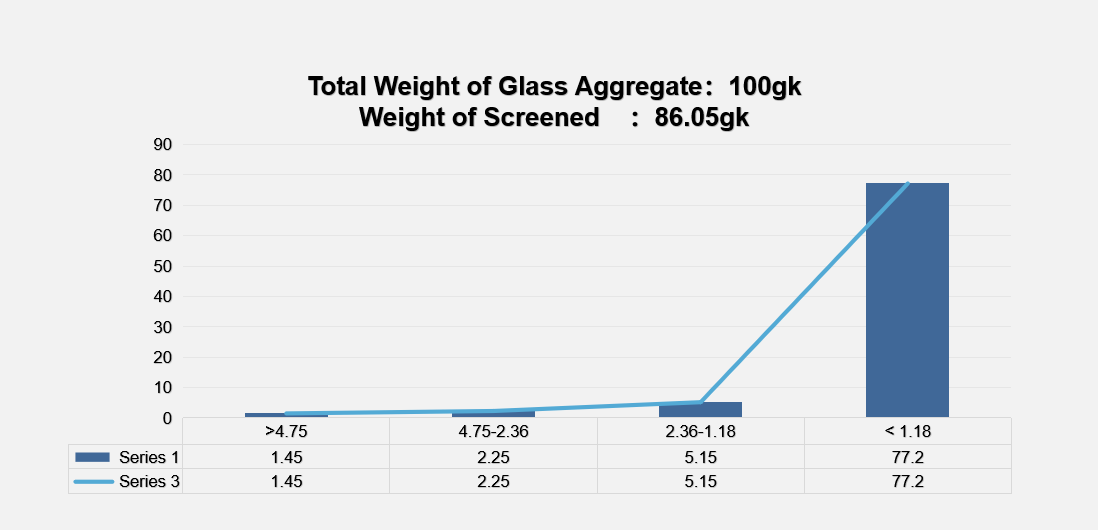

Aggregate Sample of Waste Glass after Processing by the Cage Crusher

Cage Crusher: Fine Crushing, Adapting to Diverse Recycling Needs

The cage crusher is a "shaping specialist," accurately matching the needs of different recycling scenarios.

◇ Equipped with a multi-layer cage rotor structure, the cage crusher allows flexible adjustment of crushing particle size, enabling one-click switching from coarse crushing to fine crushing. It is well-suited for various recycling applications such as asphalt mixtures and water-stabilized layers.

◇ Based on the impact crushing principle, the aggregate grinding mill produces crushed aggregate particles that are round and feature continuous gradation, effectively improving the workability and compaction effect of reclaimed mixtures.

◇ Crafted from wear-resistant materials with a sealed design, the cage crusher reduces equipment wear and dust pollution, striking a balance between durability and environmental requirements while fully complying with green construction standards.

1+1>2: Synergistic Operation, Unlocking the Optimal Solution for Aggregate Recycling

Each aggregate crushing machine performs exceptionally well on its own, and when paired with screening equipment, this combination becomes even more powerful. The synergistic operation of the aggregate grinding mill and screening systems doubles both RAP recycling efficiency and material quality.

● The streamlined process of "disaggregation first, then crushing"—powered by the cage crusher—avoids blockages caused by incomplete disaggregation and prevents aggregate waste from over-crushing, ensuring a smoother and more efficient workflow.

● The qualified rate of reclaimed materials is significantly elevated: tests confirm that RAP reclaimed materials processed by the synergistic system—centered on the aggregate grinding mill—meet all performance indicators outlined in road construction specifications and can be directly used for paving middle and lower pavement layers.

● Comprehensive costs are cut by over 30%: the aggregate crushing machine, when integrated with screening equipment, minimizes the need for new aggregate extraction and old material landfilling. This not only lowers project investment but also embodies environmental protection concepts, fully aligning with dual-carbon policy directives.

Test Data of processing through Cage Crusher and Screening equipments of Milled Asphalt Material

Test Data of processing through Cage Crusher and Screening equipments of Waste Glass

Why Choose This "Recycling Combination" ?

For engineering enterprises, the core value of the aggregate crushing machine lies in "solving problems and creating benefits."

◎Wide adaptability: The cage crusher can efficiently meet RAP processing needs under different working conditions, whether for highway overhaul, municipal road maintenance, or factory road reconstruction.

◎ Easy operation: The aggregate crushing machine—is equipped with an intelligent control system that supports one-click start/stop and adjustable parameters. This reduces reliance on labor and allows new operators to get started quickly.

◎After-sales guarantee: Comprehensive installation and commissioning, technical training, and maintenance services for the equipments ensure its stable operation without worries.

If your project is troubled by problems such as low RAP recycling efficiency, high costs, and unstable quality, this combination of attrition disaggregator and the aggregate crushing machine (or cage crusher/aggregate grinding mill) is definitely a profitable tool worth investing in.