Currently, the main production processes for manufactured sand include wet washing sand production and dry sand production. The former was widely used in the early stage of manufactured sand development but has issues like high water consumption, serious water pollution, and stone powder loss. With tower-type sand making machines applied, dry production has become a popular process in manufactured sand production lines.

Traditional Dry Sand Making Machine

Traditional dry processes use hammer crushers, impact crushers, cone crushers, or their combinations. Yet all these setups in manufactured sand production lines have drawbacks: excessive product powder content, poor particle shape, unreasonable gradation, low finished product rate, and heavy sand making machine wear.

New-Type Sand Making Equipment

Domestic enterprises now mainly adopt new dry processes centered on VSI crushers (vertical shaft impact crushers), along with roller crushers and hammer crushers in sand making machine.

VSI Crusher

A sand-making system with VSI crusher—key to a manufactured sand production line—has core crushing, screening, dust removal, and conveying modules. It drives sand making machine technology toward greenization, intelligence, and servitization. The VSI crusher-based shaping system gives the main sand making machine "crushing, shaping, sand-making, classification" functions, ensuring optimal particle shape. With vibrating screening and pulse dust collection, the manufactured sand production line yields high-quality aggregates and sand, enabling clean production.

Advantages: (1) High efficiency: The VSI crusher, core of the manufactured sand production line, handles materials well, resists moisture, and runs stably. (2) Top product quality: VSI crusher makes aggregates with few needle-like particles, round shape, and good gradation—ideal for high-grade projects, stably producing Class Ⅰ sand. (3) Compact design: An integrated sand-making tower makes the manufactured sand production line small in area, but the VSI crusher needs matching vibrating screens and bucket elevators.

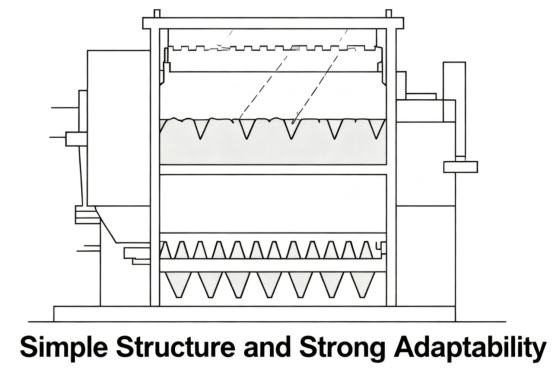

Roller Crusher

In a sand making plant, a roller crusher works by squeezing materials between two counter-rotating rollers. The roller crusher has overload protection: when meeting uncrushable objects, rollers retreat via hydraulic/spring devices to discharge them, protecting the sand making machine. Adjusting roller gaps controls output particle size, shape, and fineness modulus.

Advantages: (1) Simple structure: The roller crusher has little over-crushing, adjustable roller teeth, and handles medium-hard/soft ores. (2) High economy: Roller crusher has near 100% finished product rate, stable run, low wear, and costs for the manufactured sand production line. (3) Anti-clogging: Special-shaped rollers reduce material clogging.

Disadvantage: Output quality of roller crusher is between hammer crushers and VSI crushers—meets Class Ⅱ sand standards but not Class Ⅰ.

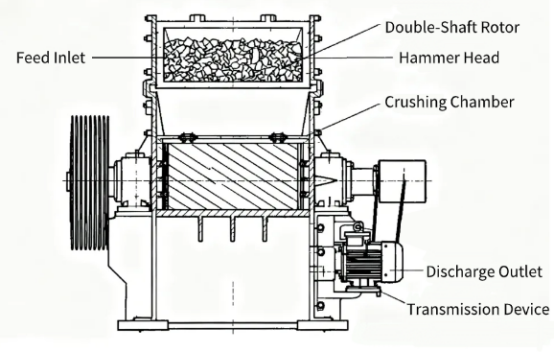

Double-Shaft Hammer Crusher

In a sand making plant, this hammer crusher’s two rotors run oppositely. Materials are struck by the first rotor’s hammers, gain kinetic energy, and are thrown to the second rotor for stronger impact. Qualified materials exit via grate gaps.

Advantages: (1) Low wear: Material collision reduces hammer consumption. (2) High efficiency: Large crushing ratio ensures high output. (3) Economical: Hammer crusher's simple structure cuts unit power consumption and manufactured sand production line costs.

Disadvantages: (1) Adjusting grate gaps needs replacement, wasting time. (2) Limited quality control—only makes Class Ⅲ sand, so few enterprises use hammer crusher in manufactured sand production lines.

Comparison of Crushers

(1) Quality: VSI crusher top (Class Ⅰ), roller crusher second (Class Ⅱ), hammer crusher lowest (Class Ⅲ). (2) Finished rate: Roller crusher and hammer crushers near 100%; VSI crushers 60%-85% (affected by model and raw material). (3) Costs: VSI crushers highest, roller crushers middle, hammer crushers lowest. (4) Environmental protection: VSI crushers (fully enclosed, efficient dust collection) are better than others.

In summary, when choosing sand making machines for a manufactured sand production line, consider costs and ensure sand quality meets downstream needs to maximize output with minimal input.