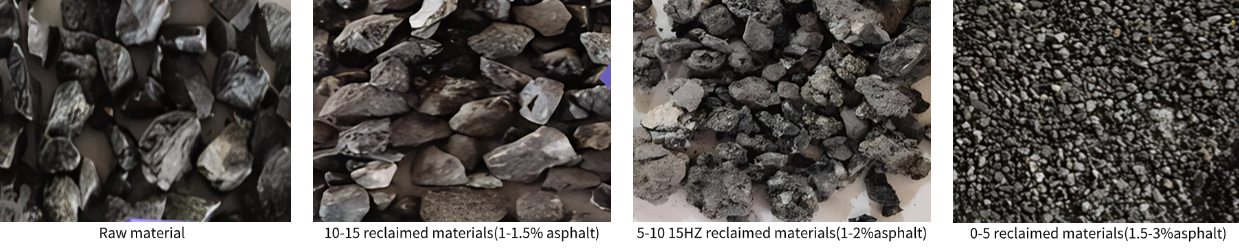

Benefiting from the dual-benefit advantages of asphalt recycling plant in environmental protection, energy conservation, and engineering cost reduction, research has found that analyzing the mix ratio and addition method of reclaimed materials reveals that their classification exerts a profound impact on the application scope, cost, and quality of output. The finer the classification, the higher the mixing ratio of RAP in the RAP asphalt aggregate recycling equipment, which endows the asphalt recycling plant with considerable economic value.

Encountered Problems

The screening, crushing and recycling processes of reclaimed asphalt pavement (RAP) via asphalt recycling plant is a complex yet crucial process. It involves the effective processing of reclaimed asphalt pavement materials through the RAP asphalt aggregate recycling equipment for reuse and incorporation into new asphalt mixtures. The high viscosity of these materials poses significant challenges to fine aggregate screening, thereby reducing the value of RAP processed by the RAP asphalt aggregate recycling equipment. How can the workflow of the asphalt recycling plant be simplified to maximize effectiveness and enhance productivity within limited space?

Solution

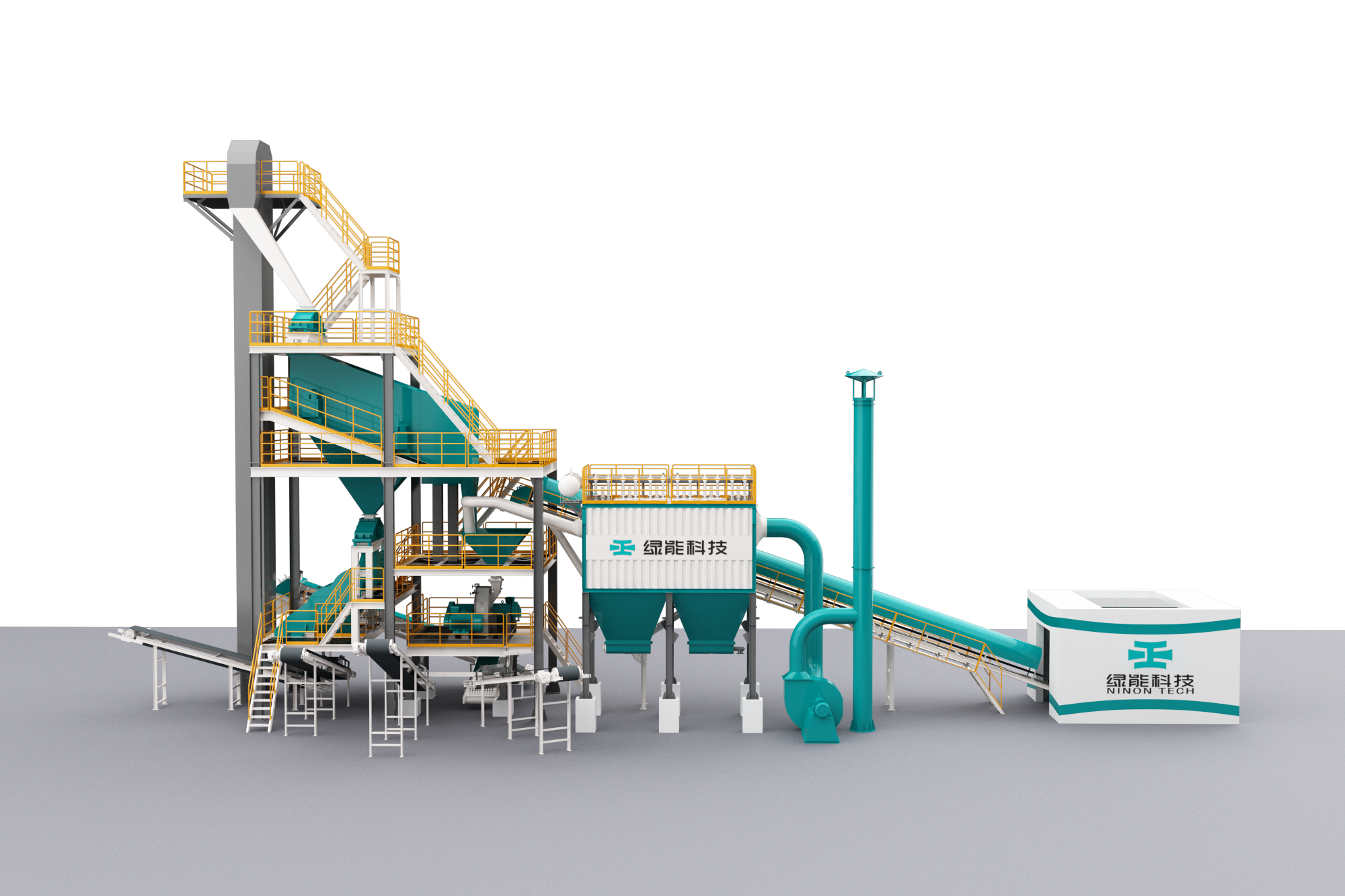

Ninon's R&D team has conducted in-depth and continuous research on reclaimed material crushing and screening technology, and developed the state-of-the-art asphalt recycling plant. Based on the most advanced flexible tooth roll crushing and screening technology, this RAP asphalt aggregate recycling equipment can easily address the challenges of fine reclaimed aggregate screening as well as the crushing and screening of moist and cohesive aggregates.

Technical Features of Ninon's Asphalt Recycling Plant

The asphalt recycling plant adopts flexible crushing technology. The crushing teeth feature a sloped structure on one side, which serves a force-relief function to avoid damaging the original gradation caused by hard extrusion of aggregates in the asphalt recycling plant. The crushing teeth between the two roller heads are staggered and interlocked, arranged asymmetrically along the axial direction. When reclaimed materials pass through the roller gap, they undergo simultaneous axial movement to achieve rubbing and separation. This asphalt recycling plant exerts shearing, extruding, and bending actions on pavement reclaimed materials. Compared with jaw crushers and impact crushers, the asphalt recycling plant reduces impact on reclaimed materials, thereby lowering dust emissions and ensuring stable operation. The kneading-like crushing action on reclaimed materials greatly minimizes the crushing of large particles, realizing the breaking and squeezing apart of reclaimed materials. This reduces the generation of fine materials and helps retain the original gradation ratio of RAP.

The two counter-roll crushing heads adopt a planar differentiated arrangement (horizontal offset), which increases the meshing area of the crushing teeth, thereby enhancing the capacity of the asphalt recycling plant.

The RAP asphalt aggregate recycling equipment operates at low speed, which enhances the kneading effect of the crushing tooth rolls on materials and further reduces the hard impact and extrusion on reclaimed materials. This achieve true flexible crushing, minimizes the generation of fine crushed materials and new aggregate cross-sections, and lowers asphalt binder consumption.

The screening system adopts the same structure as the vibrating screen of asphalt mixing plants. Whether producing 2 or 3 grades of materials, the RAP asphalt aggregate recycling equipment integrates the function into a single vibrating screen, which reduces the site layout area.

Ninon's RAP asphalt aggregate recycling equipment can be flexibly adjusted according to requirements. The asphalt recycling plant can produce 2-5 grades of materials, which are stored in separate piles. The common gradation ranges are 0-3-5-12-16-22 (25) mm, effectively controlling moisture content and preventing the agglomeration of mixed materials in the asphalt recycling plant.

This asphalt recycling plant is designed with a fixed and modular structure, which features easy installation, greater convenience for relocation, a small footprint, low noise level, and a high operational safety factor. With a low overall height, the RAP asphalt aggregate recycling equipment is easy to install in limited spaces and facilitates production line layout.

Amid the trend of iterative upgrading in pavement waste material recycling technology, for engineering projects requiring high-proportion RAP recycling technology, Ninon's RAP asphalt aggregate crushing and screening equipment stands as the "core enabler" to guarantee construction quality. Backed by years of technical accumulation and practical verification from numerous implemented projects, it comprehensively empowers your projects—from cost optimization to construction quality enhancement. It is the optimal choice for you to layout green road engineering and achieve benefit breakthroughs.