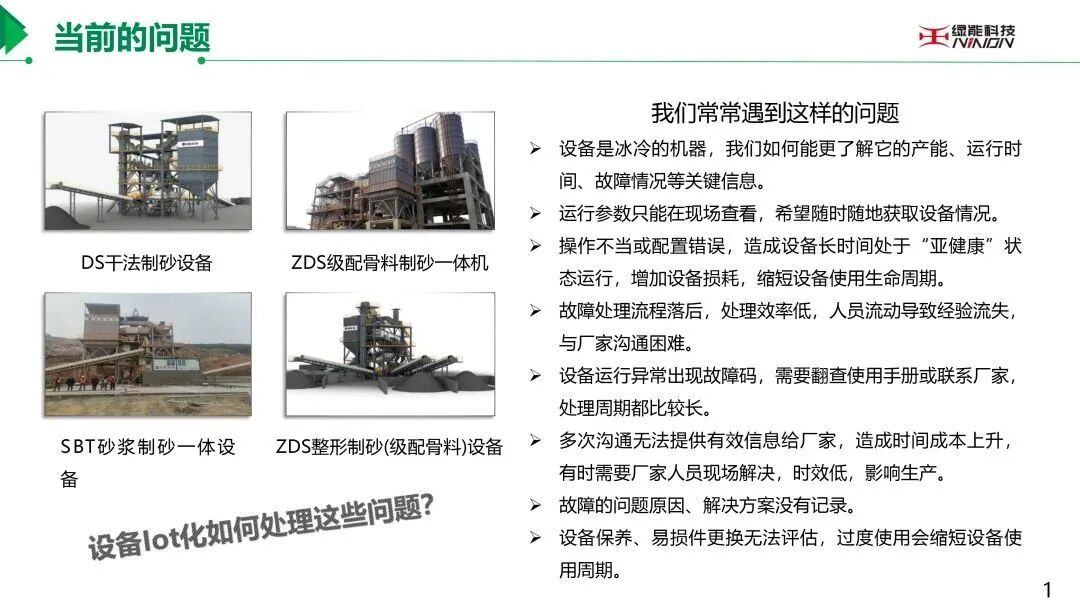

Nowadays, as equipment manufacturers expand their business, the growing number of devices—especially high-demand equipment like sand making machines—and the continuous upgrading of equipment processes have made traditional on-site manual maintenance increasingly challenging and costly.

A single sand making machine in a aggregate production line, for example, involves core components such as the crushing cavity, impeller, and transmission system; any failure requires on-site technicians to travel, which not only delays repairs but also increases labor and transportation costs. Meanwhile, users’ requirements for equipment maintenance (including sand making machines) are constantly rising—they expect minimal downtime, real-time status monitoring, and rapid fault resolution—posing numerous challenges to equipment manufacturers.

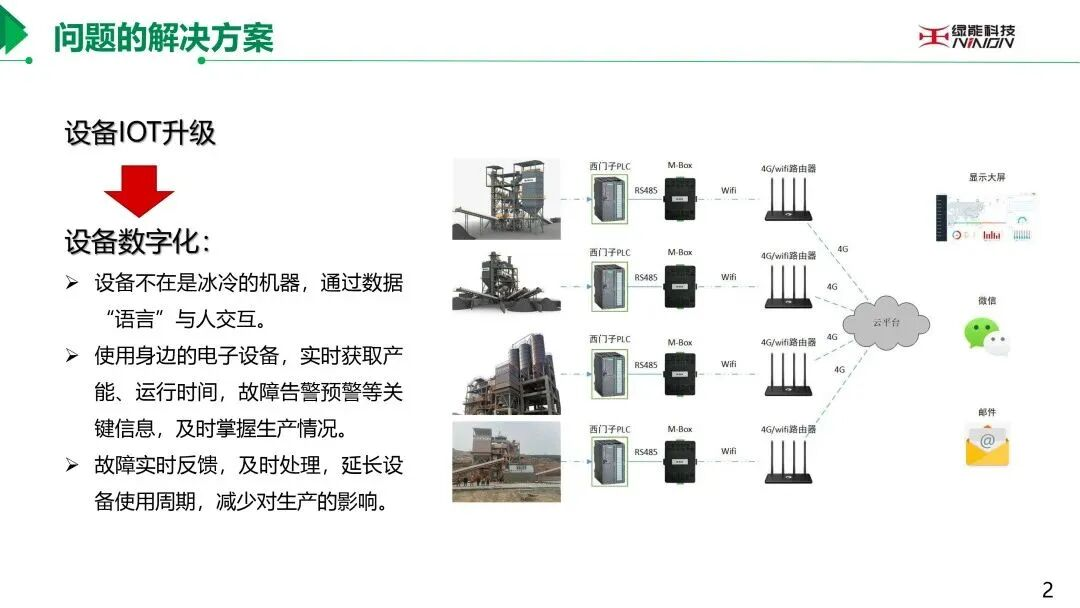

Remote intelligent operation and maintenance (O&M) of equipment is a key manifestation of digital transformation and development, and also one of the core application directions for equipment manufacturing enterprises to deeply integrate the industrial Internet of Things (IIoT), big data, and artificial intelligence. For equipment like sand making machines, which are often deployed in harsh environments such as quarries or construction sites, remote intelligent O&M is not just a convenience but an inevitable path for efficient equipment management.

Compared with the traditional O&M service model, Ninon's remote O&M has obvious advantages in improving efficiency, enhancing service quality, and saving costs—especially for sand making machines. Relying on Ninon's remote O&M services, the time and space boundaries of sand making machine maintenance are broken: when a sand making machine shows abnormal vibration (a common precursor to impeller wear), the platform can immediately send an alert to both the user and Ninon’s technical team, enabling rapid and timely responses to O&M needs without waiting for on-site personnel to arrive.

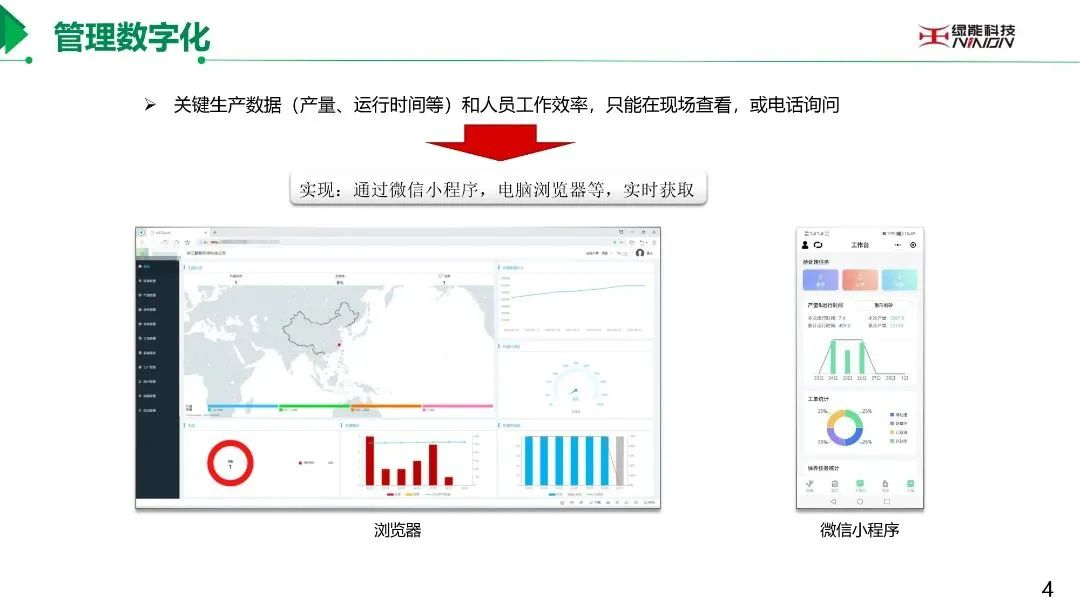

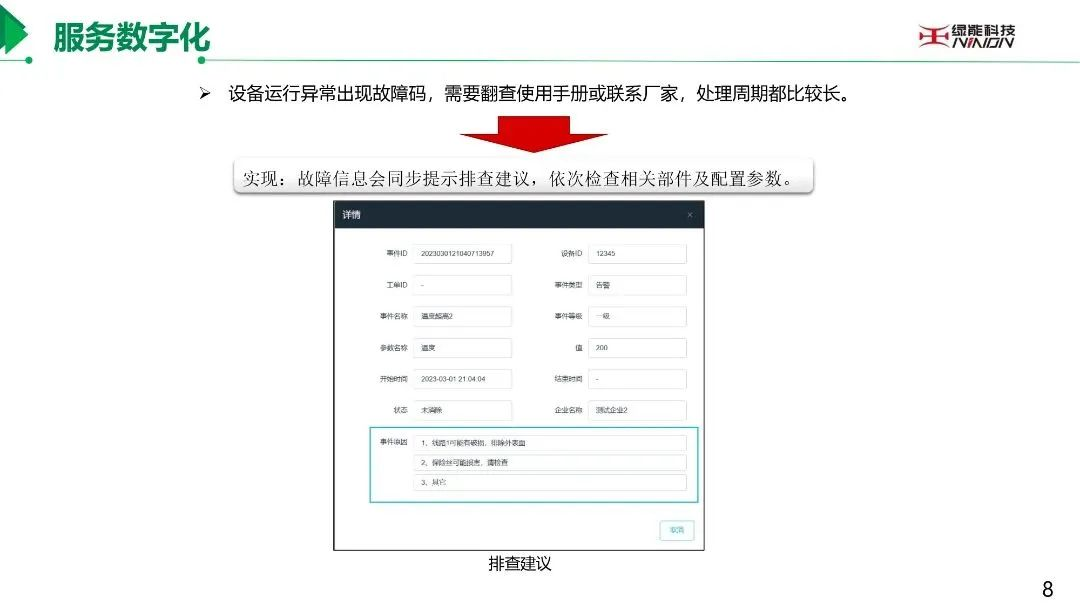

Ninon can proactively obtain the operational status information of sand making machines (and other equipment) through its remote O&M system. When a sand making machine malfunctions—such as a blockage in the feeding port—early warning and alarm signals are generated immediately. Through the platform’s real-time data visualization function, technicians can clearly see the on-site sand making machine status at a glance: whether the motor is overheating, whether the discharge volume is reduced, and which specific parts (e.g., the feed hopper or the crushing plate) require maintenance or servicing.

This new after-sales model significantly reduces the downtime of equipment due to faults: for a sand making machine that originally required 2-3 days of on-site maintenance, remote O&M can shorten the repair time to within 24 hours. It also improves the utilization efficiency of sand making machines, greatly enhances the company's service efficiency and quality, and accelerates the informatization process of equipment management for users—helping aggregate production enterprises relying on sand making machines to achieve more stable and efficient production.