In the field of construction engineering, the characters sand (small particle size) and sand (relatively large particle size) may seem similar, but they actually differ significantly. They each have unique characteristics in terms of meaning, formation process, and application scenarios. Next, we will delve into their differences from multiple perspectives.

Core Differences

(1) Particle Size and Application Scenarios

The first one generally refers to sand and gravel particles with smaller particle sizes, and is commonly found in written and literary works, such as expressions like sandy beach, flying sand and rolling stones.

Another one refers to sand and gravel particles with slightly larger particle sizes, and is mostly used in scientific research fields because its larger particles facilitate research. It is worth noting that in civil engineering, regardless of particle size, sand and gravel particles are collectively referred to as "sand", products made by sand making machine is sand, and the material used in concrete mixing is also "sand".

(2) Sources and Formation Methods

Sand (small particle size) is mainly formed by the forces of nature. It is a common substance in rivers, beaches, deserts and other places, and is the product of long-term wind and water action. The sand particles are characterized by being smooth and fine.

Sand (relatively large particle size) is mainly produced through artificial processing such as ore crushing and sand making machine. Its particles are coarser and angular, and it is widely used in construction, road construction and other engineering projects.

Claasification and Characteristics of Sand (relatively large particle size)

(1) Sand is mainly divided into two categories: natural sand and manufactured sand

Natural sand: Formed by the action of natural conditions, rocks gradually turn into sand through wind, rain, and daily weathering. Its particle size is generally below 5mm, and it feels relatively fine due to being washed by water and rivers.

Manufactured sand: Also known as artificial sand, it is made by crushing stones with sand making machines by humans, and has a relatively inferior feel.

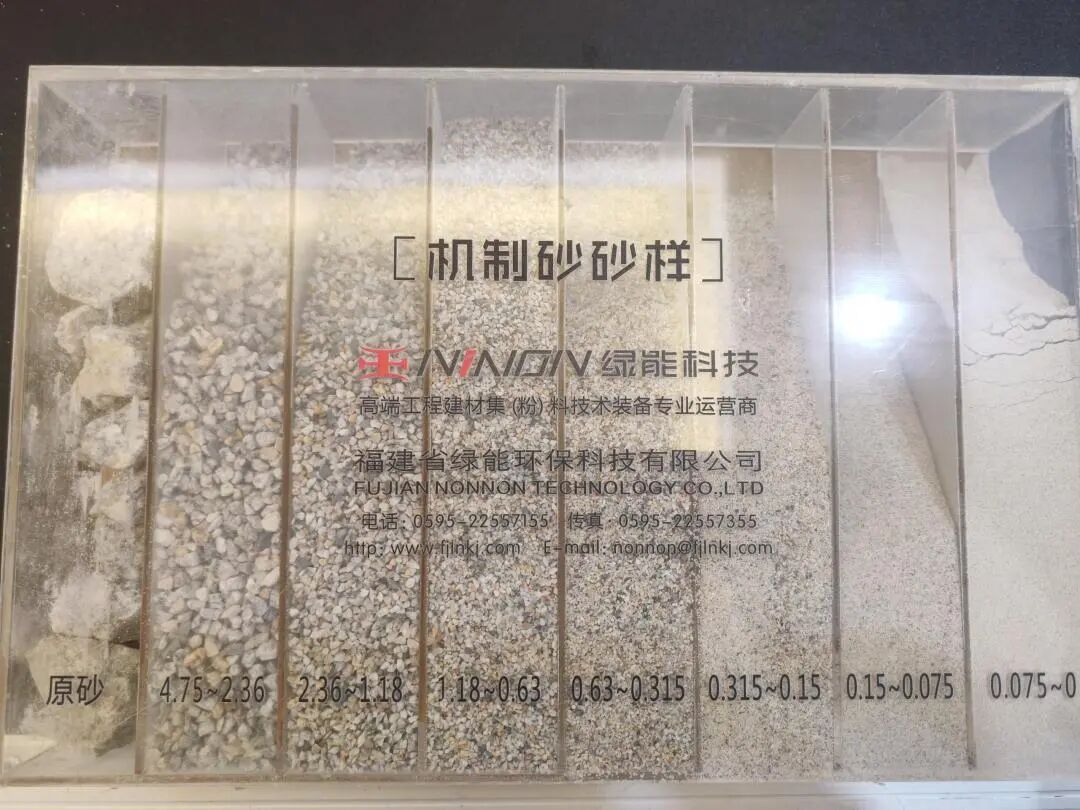

(2) Detailed Description of Manufactured Sand

Manufactured sand is a product obtained through multiple sophisticated processes using sand making machines or other professional equipment, featuring excellent particle shapes. During the manufacturing process, sand making machine can be flexibly selected to produce machine-made sand of different specifications according to specific material requirements, so as to meet diversified needs.

Studies have shown that there is no significant difference in the performance between concrete made with machine-made sand and that with natural sand. However, to achieve the same slump, machine-made sand concrete requires a slightly larger amount of water, and the actual water consumption should be determined by comprehensively considering factors such as construction conditions, structural requirements, and transportation. The sand produced by sand making machine has little impact on the strength of concrete, but when producing special concrete that needs to be pumped, the sand ratio must be carefully controlled. An excessively high sand ratio may reduce the strength and durability of the concrete, thereby affecting the engineering quality.

Production Process

(1) Pretreatment Stage

At this stage, impurities such as waste wood and plastics need to be picked out from the mixed soil and stones. To separate waste iron materials more efficiently, magnetic separation can also be used in the sand making machine.

(2) Raw Material Crushing Stage

The raw materials are evenly fed into the coarse crushing equipment by a vibrating feeder, and either a jaw crusher or a hammer crusher is selected for crushing according to the hardness of the stones. After coarse crushing, qualified materials are conveyed to the fine crushing equipment (parts of the sand making machine) via a belt conveyor for further processing, while unqualified materials are returned to the coarse crushing equipment for re-crushing.

(3) Sand-making Stage

The crushed small stones are further finely crushed and shaped by a sand making machine to make their particles more uniform.

(4) Finished Product Screening Stage

With the help of a circular vibrating screen, sand is classified into coarse sand, medium sand and fine sand as required, resulting in construction sand of different specifications.

(5) Sand Washing Stage

Specialized sand washing equipment is used to clean the sand, removing soil and other impurities to ensure the quality and cleanliness of the sand.

In regions lacking natural sand resources, the rational application of machine-made sand production technology can not only meet construction needs but also achieve a win-win situation in terms of economic and social benefits.