The national standard GB/T 14684-2022 Sand for Construction, initiated and overseen by the China Building Materials Federation, jointly revised by the China Sand and Gravel Association, Beijing University of Civil Engineering and Architecture, and other institutions, was officially released on April 15, 2022, and took effect on November 1 of the same year. Compared with the 2011 version, this new standard has key revisions in terminology, general provisions, technical requirements, test methods, and inspection rules—with a strong focus on guiding the development of the manufactured sand sector, closely tied to the optimization of the manufactured sand production line.

In terms of definitions, the new standard clarifies "manufactured sand" as particles smaller than 4.75mm, made from rocks, pebbles, mine waste rocks, or tailings via processes like soil removal, mechanical crushing, shaping, screening, and powder control (with qualified gradation, particle shape, and stone powder content), excluding soft and weathered particles. This definition directly aligns with the core processes of a modern manufactured sand production line, providing clear technical benchmarks for each link of the production line—from raw material selection to shaping and powder control. It also defines "methylene blue (MB) value" as an indicator for manufactured sand’s adsorption performance, a key parameter that manufactured sand production lines need to monitor and adjust to ensure product quality. Additionally, "blended sand" (mixed manufactured and natural sand) and "flaky particles in manufactured sand" (for particles over 1.18mm) are newly defined, further standardizing the quality control of manufactured sand production lines.

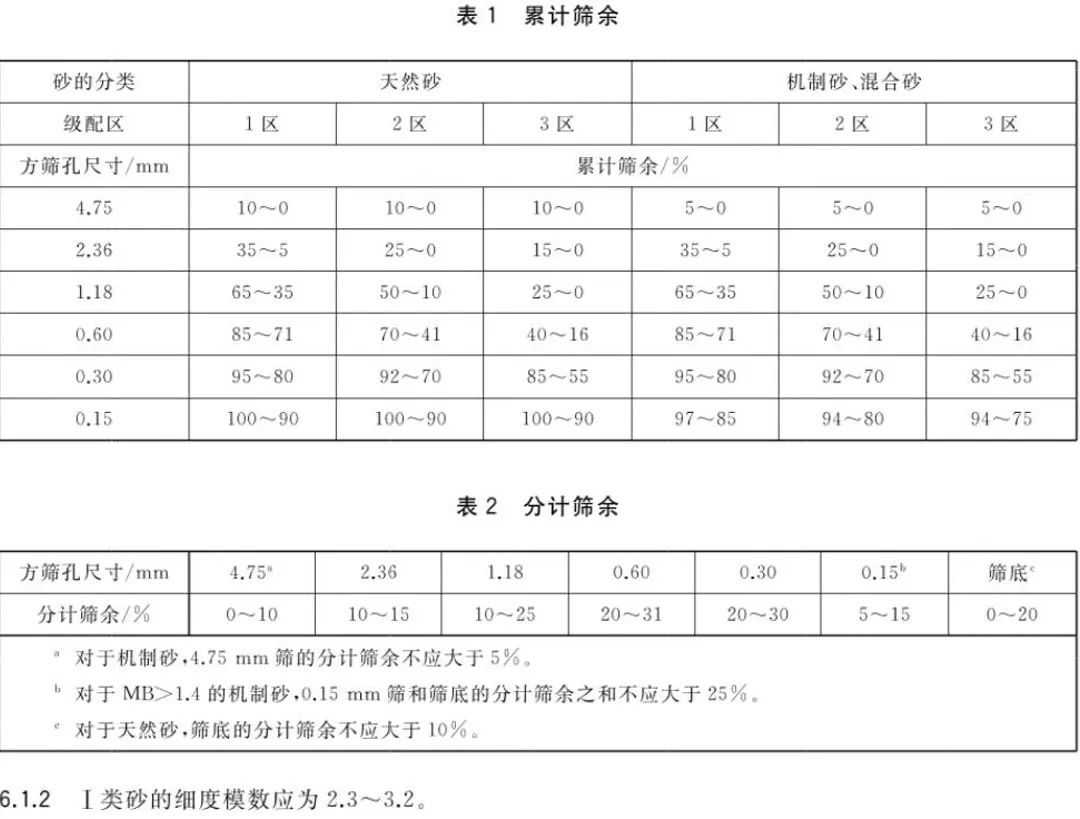

In classification, the new standard adds the fineness modulus range for extra-fine sand, revises Class Ⅰ sand’s gradation requirements, and supplements fractional sieve residue indicators and fineness modulus rules. These revisions directly guide the configuration of screening and grading equipment in the manufactured sand production line—for example, helping enterprises adjust screen specifications or add grading modules to meet the new gradation standards, ensuring the produced manufactured sand meets different project needs (such as high-strength concrete for bridges).

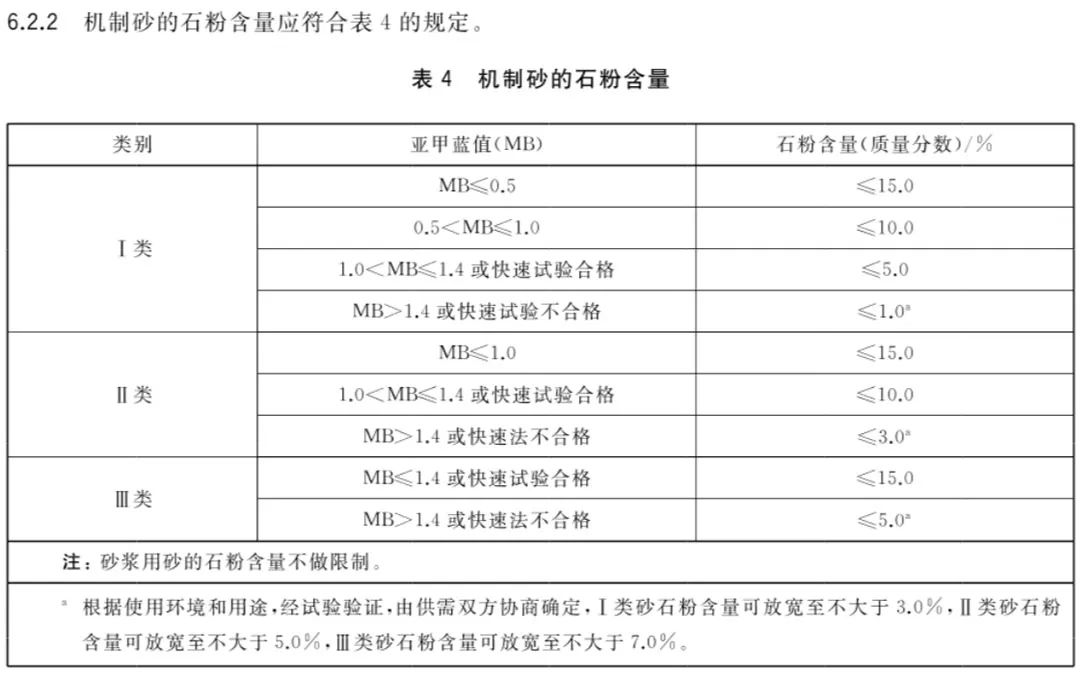

The technical requirements for the stone powder content in manufactured sand have been revised.

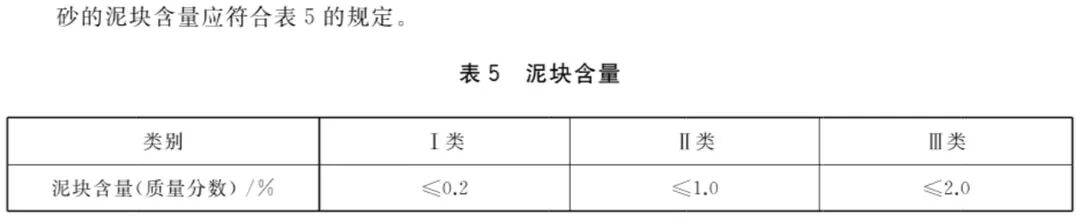

Technical requirements for the content of clay lumps:

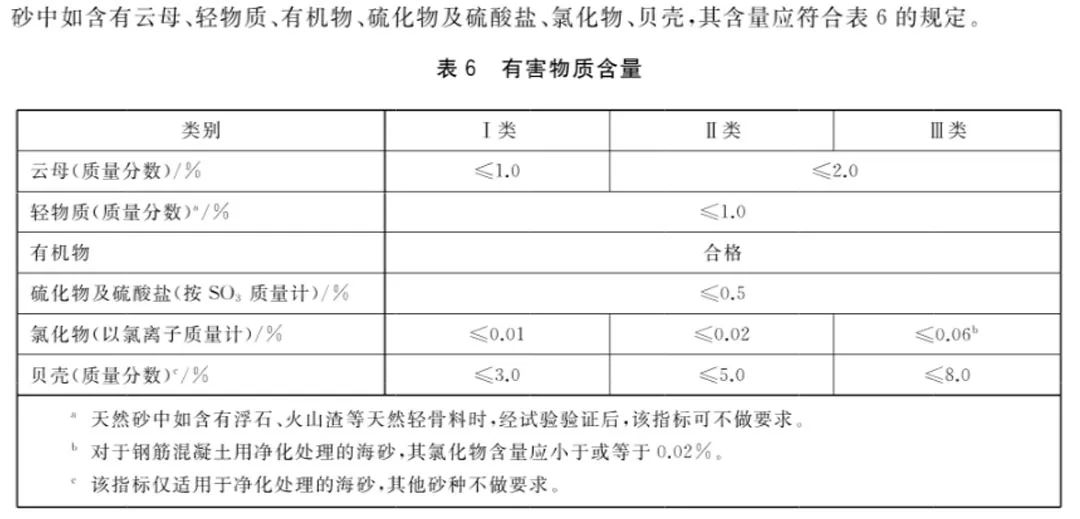

Technical requirements for harmful substances, etc.

The requirement for the content of flaky particles in Class I manufactured sand is specified as ≤10%.

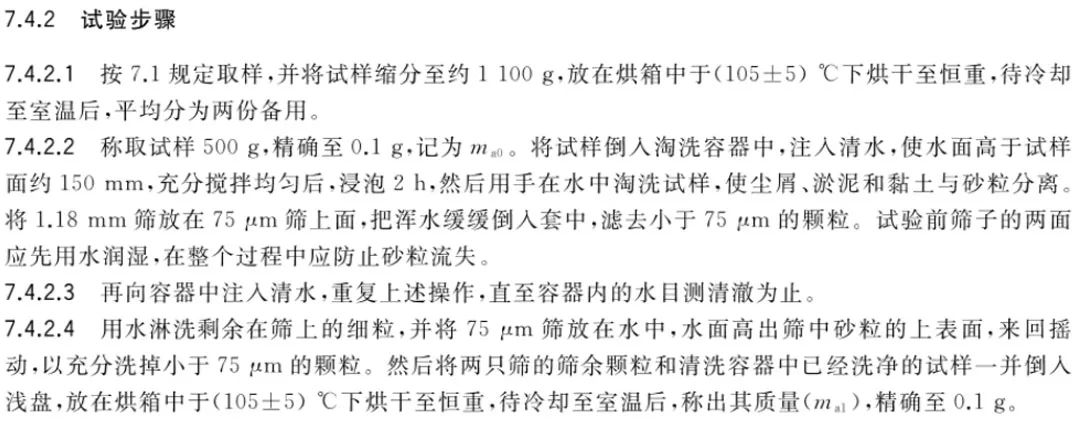

The test method for the content of clay lumps has been revised.

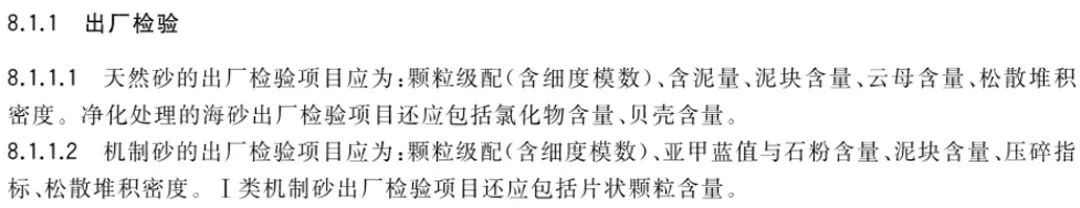

The inspection items and batch grouping rules have been revised.

The revision’s significance lies in solving industry pain points: with natural sand depletion, the manufactured sand production line has become critical, but inconsistent old standards hindered its development. GB/T 14684-2022 unifies manufactured sand’s quality indicators, enabling manufactured sand production lines to have clear technical guidelines—reducing substandard products, boosting supply capacity, and supporting infrastructure. It also promotes the green transformation of the manufactured sand production line, as the standard encourages using mine waste rocks/tailings as raw materials, aligning with ecological protection and driving the sand and gravel industry toward high-quality development.