Qianxian County DS100 Sand-Making Equipment

Handan ZDS200 Sand-Making Equipment

Yichun project of Jiangxi Transportation Engineering Group's second 100T/h sand - making production line

DS Sand-Making Equipment Being Installed in Wannian County

The Second Set of ZDS1030 Sand-Making Equipment in Xiaoshan

The Second Set of ZDS1030 Sand-Making Equipment in Shaoxing

Nowadays, "environmental protection" has become a key social focus. As the country strengthens ecological balance and tightens environmental protection policies, large-scale river sand exploitation has been gradually prohibited by the government. To address this, Ninon’s manufactured sand production line emerges as a critical solution: it not only effectively mitigates ecological damage caused by river sand mining but also fulfills society’s demand for sand in concrete, mortar, and other construction scenarios.Ninon’s high-quality aggregate shaping manufactured sand production line is designed with environmental protection at its core, featuring a fully enclosed structure. All conveyor belts and pipelines are sealed to prevent dust leakage, and small dust collectors are installed at major corners to capture scattered particles. More importantly, key equipment in the manufactured sand production line —such as crushers, powder separators, and screening machines—adopts centralized dust removal systems, which fundamentally control dust pollution. This well-designed manufactured sand production line requires no additional encapsulation, enabling fully eco-friendly and green production. Its organized emission concentration can reach below 10mg/Nm³, fully meeting and even exceeding national environmental standards, making it a model for sustainable sand-making.

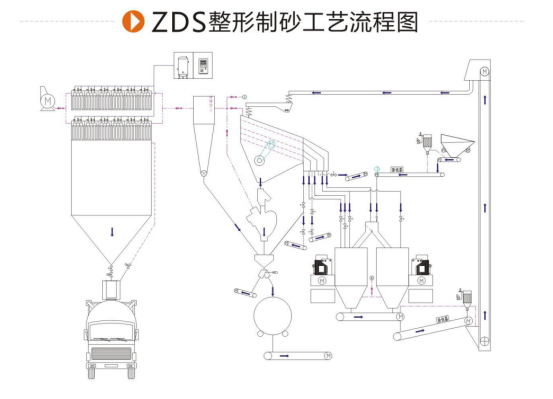

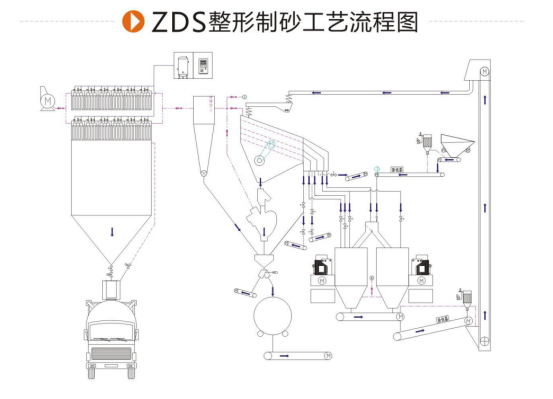

Beyond environmental performance, Ninon’s equipment also excels in functionality and customization. The ZDS series sand making plant, an upgraded version of the DS pure sand-making model, adds a professional shaping function. While producing sand and gravel, this sand making plant optimizes the particle shape of the finished product, making it more uniform and aesthetically pleasing—enhancing the quality of concrete and mortar applications. Additionally, the ZDS series sand making machine is equipped with multiple discharge belts, allowing it to produce sand and gravel of different specifications simultaneously. This flexible design of the manufactured sand production line caters to diverse customer needs, whether for small-batch specialized sand or large-scale multi-specification aggregate supply.

The ZDS shaping and sand-making equipment adds a shaping function on the basis of the DS pure sand-making equipment, making the produced sand and gravel more aesthetically pleasing while outputting them. Moreover, with multiple discharge belts, it can produce sand and gravel of different specifications, which can more thoughtfully meet customer needs.

For the goals of green development, eco-friendliness, energy efficiency, and high performance, Ninon has always focused on refining its manufactured sand production line and specialized in advancing this core product. In the future, Ninon will continue to upgrade the technology and performance of its manufactured sand production line, providing customers with higher-quality equipment and services, and jointly creating a new win-win cooperation model for the sand and aggregate industry’s sustainable development.