Zhejiang Pantai Environmental Protection Technology Co., Ltd., an integrated supplier of high-quality sand and gravel, mortar, and asphalt mixtures, is adjacent to Provincial Highway S331, enjoying convenient transportation and a wide radiation range. Its products cover the county and extend to Cangnan, Longgang, Pingyang, Fuding, etc. Driven by urbanization and key project construction, the high-end building materials market has huge space.

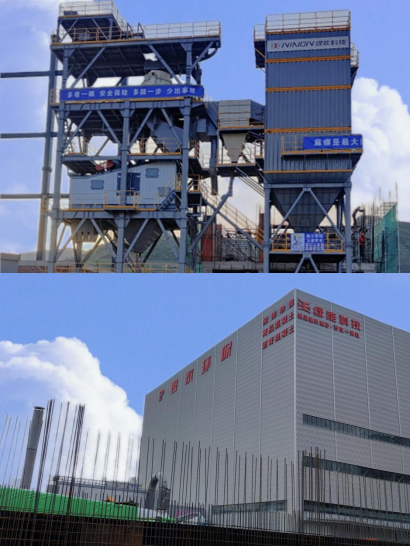

Thus, in 2021, Zhejiang Pantai launched a 300,000 tons/year integrated production line project for shaped sand-making and ready-mixed mortar, which adopts three-in-one equipment independently developed by Fujian Ninon Technology Co., Ltd.—including ZDS1030 high-quality aggregate shaping and sand-making production line (a core part of aggregate processing equipment), SBT80 mortar integrated production line (equipped with a high-efficiency mortar mixer), a drying system, and also supports matching with RAP asphalt recycling plant for asphalt mixture production.

The project was put into operation in November 2022, featuring high efficiency, quality, operation rate, intelligence and low cost, bringing significant benefits. As early as 2019, Pantai purchased DS100 shaping and sand-making equipment (another type of aggregate processing equipment) from Ninon, whose finished sand was applied to asphalt road construction, laying a foundation for later matching with RAP asphalt recycling plant.

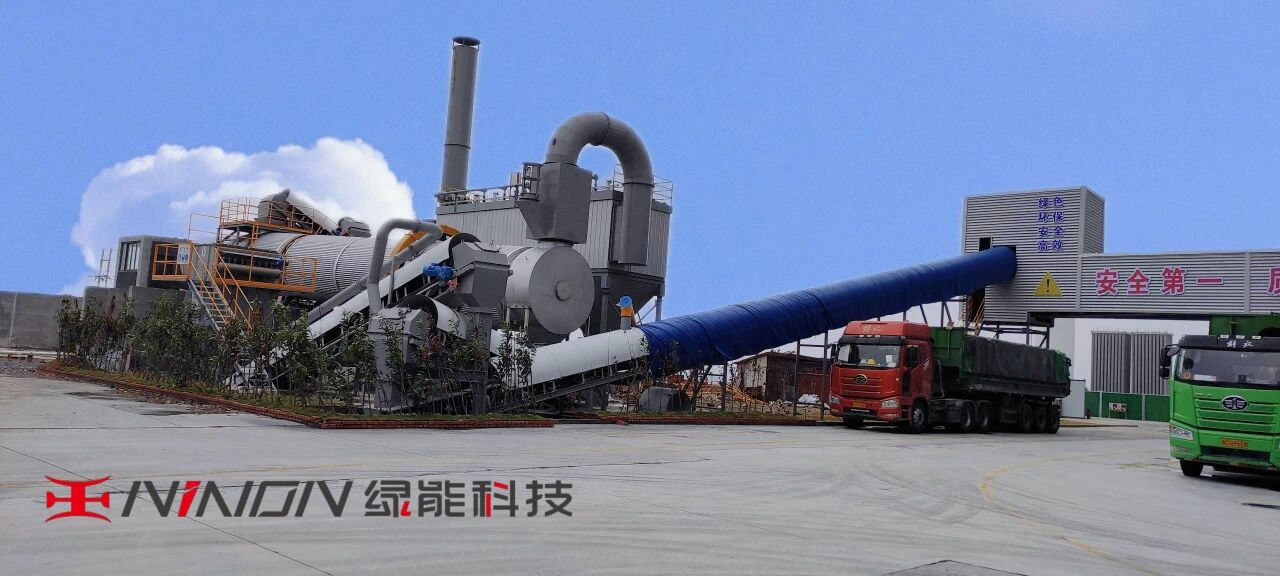

The production line process starts with drying: purchased stones are heated by a natural gas-fired drying system to remove moisture, preparing for aggregate processing equipment. Then, shaping and sand-making: dried stones are sent to aggregate processing equipment via an elevator, which has a 5-layer heavy-duty linear screen and switchable production modes. For asphalt materials (supporting RAP asphalt recycling plant’s raw material needs), it produces 0-4mm, 4-10mm, 10-16mm, 16-26mm products; for mortar sand, it produces 0-2mm products.

Next is screening: materials from aggregate processing equipment such as RAP asphalt recycling plant are screened by a vibrating screen—qualified fine sand enters stone powder separation, while oversize materials are re-conveyed to the shaping crusher for reprocessing. In stone powder separation, a large-particle recoverer retrieves large particles, which are sent to the finished sand silo with deslimed sand; 200-mesh stone powder is filtered by a dust collector into the stone powder silo.

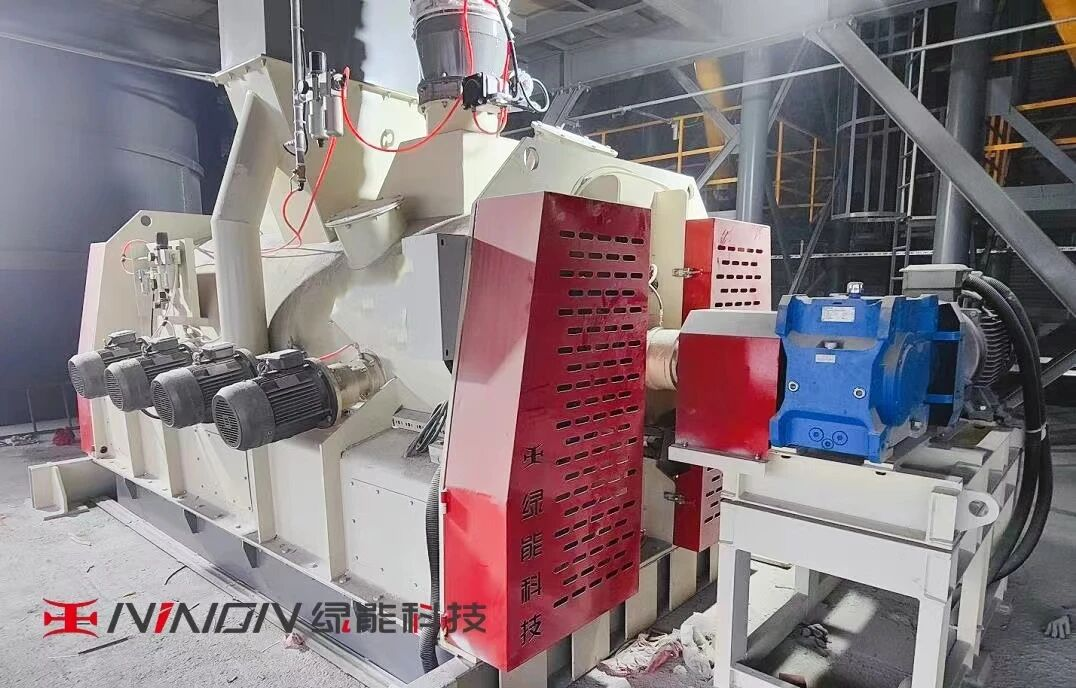

For mortar production: raw materials like cement, fly ash, thickening powder and stone powder are conveyed to silos via a closed system. Sand is lifted to the silo, and metered sand is fed into the mortar mixer’s feeding port. Powdered raw materials are sent to a weighing scale via a closed screw conveyor, then into the mortar mixer after metering. The mortar mixer’s working principle: under mutually reversing stirring shafts, materials are affected by circumferential, radial and axial forces of blades, undergoing intense mixing through extrusion, friction, shearing and convection, and moving to the discharge port, ensuring uniform mixing. Dry-mixed mortar then enters the finished product silo via a closed system—bulk products are transported by tank trucks, while some are bagged in the bagged warehouse.

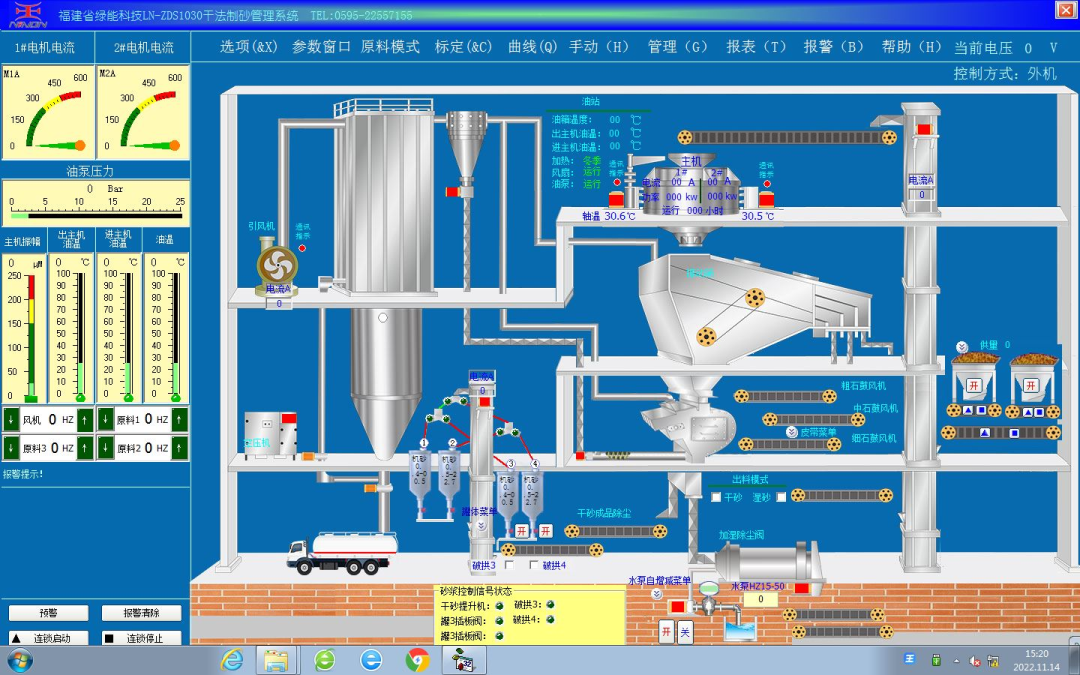

The production line uses an automated control system with industrial computer + Siemens PLC + touch screen, dynamic 3D interface and one-key operation. It has online sensors for real-time monitoring, early warning and remote maintenance. Compared with traditional processes, it avoids dust pollution. The tower-type structure saves space. All raw materials are automatically metered (with manual admixture ports). The mortar mixer’s mixing uniformity is ≥98%, finished product silo discharge uniformity ≥95%. Dust emission ≤10mg/Nm³, factory boundary noise ≤55dB(A). It also has safety facilities, product cross-contamination and segregation prevention measures, and raw material/finished product statistics function. For asphalt-related production, it can be flexibly matched with RAP asphalt recycling plant to realize resource recycling, further enhancing environmental and economic benefits.

In conclusion, Ninon’s integrated production line (with aggregate processing equipment as core) at Zhejiang Pantai excels: aggregate processing equipment and RAP asphalt recycling plant raw needs, the mortar mixer ensures ≥98% mixing uniformity, and the line’s low emissions align with green goals. It boosts Pantai’s efficiency, supports high-end building demand, and sets an industry model for integrating aggregate processing, mortar mixing, and asphalt recycling.