Growing Media and Its Related Terminology Glossary

Sand Making Machine: Core Drivers for Efficient Soil Substrate Preparation

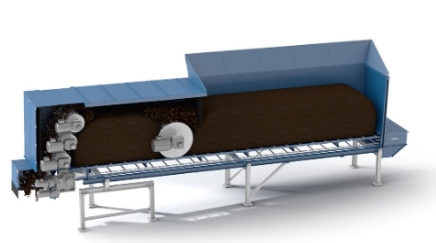

In soil substrate production, high-quality aggregates directly determine the substrate’s looseness, permeability, and water-fertilizer retention capacity—and the manufactured sand production line, with the sand making machine as its core, has become an indispensable solution for substrate enterprises aiming to cut costs and boost efficiency.

A well-designed manufactured sand production line integrates crushing, grinding, screening, and impurity removal, while the sand making machine at its heart ensures precise processing: it can turn mine waste, construction waste, or other low-cost raw materials into high-quality manufactured sand with uniform particle size (0.15-5mm) and optimized gradation—perfectly meeting the strict aggregate standards of soil substrates. This not only replaces scarce traditional natural sand (solving raw material shortage issues) but also guarantees stable aggregate quality, a key advantage over random sand sources. The sand making machine is equipped with wear-resistant hammers and intelligent speed control systems, enabling a sand production rate of over 95% and producing rounded sand particles without sharp edges—this avoids scratching plant roots and significantly enhances the safety of the final soil substrate.

What makes the manufactured sand production line even more valuable is its efficiency and flexibility: with the sand making machine as the core, the line achieves simultaneous crushing, screening, and impurity removal, boasting an hourly capacity of 50-200 tons to satisfy large-scale soil substrate production demands. Compared to purchasing external aggregates, using a manufactured sand production line (powered by a high-performance sand making machine) to produce sand in-house reduces raw material costs by over 30%. Additionally, the sand making machine allows easy adjustment of sand particle parameters, letting enterprises tailor aggregates to different substrate formulas—whether for seedling cultivation, potted plants, or professional horticulture.

For soil substrate enterprises looking to stay competitive, investing in a reliable manufactured sand production line and a high-quality sand making machine is a strategic choice. It not only streamlines production and controls costs but also ensures consistent substrate quality, helping you seize more opportunities in the horticulture and agricultural planting markets!