Soil Types

To determine the most suitable soil stabilization method for your application, it is first necessary to understand the type of soil you are dealing with. Soils are mainly categorized into four types: sand, silt, clay, and loam. Each type of soil has distinct characteristics and requires different stabilization treatments.

One of the most important factors to consider when conducting soil stabilization is the organic matter content of the soil. The organic matter content is typically measured by the soil's plasticity index, which is derived from the Atterberg test. Understanding the organic matter content is crucial because it helps you comprehend how the soil's shape will change. Soils with low organic matter content generally do not deform when wet, whereas those with high organic matter content undergo significant shape changes when moistened.

Relevant Soil Treatment Equipment

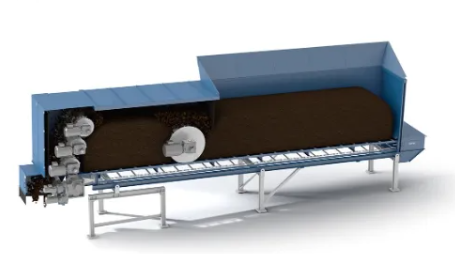

1. Sludge Crushing Machine

Since silt is formed by the erosion and weathering of rocks, it contains some quartz but has very low organic matter content. However, it is generally dense and tends to settle at the bottom of standing water. Silty soils are ideal for crop cultivation as they are usually rich in a large amount of nutrients required by crops. Sludge crushing machine can be utilized to adjust the particle size and density for compaction.

Sludge Crushing Machine ( Sludge Homogenizing Machine)

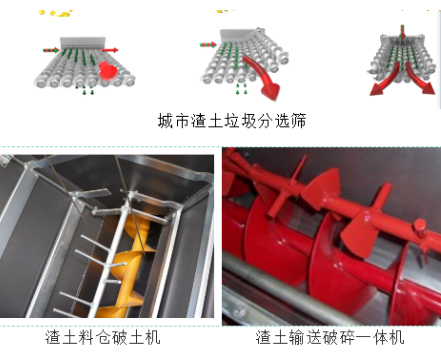

2. Clay Treatment Equipment: crushing machine

Among all soil types, clay has the smallest particle size. Beyond particle size, the most significant difference between clay and other soil types is its plasticity when moist. Due to its plasticity, the expansion and contraction of clay present significant challenges for construction activities conducted on it. Typically, clay-based soils are either excavated and removed from construction sites, processed with crushing machine, or treated with chemicals or additives to achieve permanent hardening.

3. Integrated Muck Conveying and Crushing Machine

Loam is a mixture of sand, silt, and clay. Each classification and type of loam varies according to the characteristics of its dominant soil component. To identify different soil types, tests such as sieve analysis can be conducted to determine particle size, and Atterberg tests to assess soil plasticity and organic matter content. Muck and waste can be treated using muck conveying and crushing machine.

Muck Silo Soil Breaker、Integrated Muck Conveying and Crushing Machine

4. Lime Crushing Machine

Fly ash is a by-product of coal from coal-fired power plants. It can also be used as a binder to enhance soil strength, with its primary application being the treatment of subbases for paved roads. As a dry additive, one significant advantage of using fly ash regularly in soil is that it helps address soil with moisture levels exceeding the optimal range. The powder absorbs water, thereby reducing the soil's moisture content. Therefore, homogenizing and crushing machine can be used to improve the properties of the required soil.

Lime Slaking, Crushing and Homogenizing Machine