During our recent after-sales follow-up, we received feedback from the client——Hangzhou Guanghua Luqiao Engineering Co., Ltd. : The DS60 Sand Making Plant, delivered and installed in 2017, has gone through 8 years of production trials within their manufactured sand production line, with a total operating time exceeding 6,000 hours. Over the years, supported by our timely after-sales service, Ninon has assisted the client in maintaining this sand making machine to ensure the entire aggregate shaping and sand making plant maintains continuous and stable production capacity. This on-site usage feedback is not only a direct recognition of the sand making plant's performance, but also serves as the most authentic testimony to the quality of our sand making equipment.

For sand and gravel production enterprises, the "durability" of a sand making machine is never an abstract concept, but a key factor directly linked to the efficiency of the manufactured sand production line, operation and maintenance costs, and project profits. This DS60 Sand Making Plant has been "in service" as the core of the production line for 8 years. Behind its continuous operation of over 6,000 hours lies stable output day and night for the entire line: from the crushing and processing of different raw materials such as granite and limestone to meeting the high-intensity production demands during peak periods, this sand making machine has always maintained stable processing capacity, with no long-term shutdowns of the manufactured sand production line caused by core component failures.

The client mentioned during communication that they initially chose the DS60 Sand Making Plant precisely because of its modular design and high-strength wear-resistant components—features critical for a heavy-duty sand making machine. After 8 years of use, the replacement frequency of the sand making plant's wearing parts is lower than expected, and the accuracy of the core system, which directly affects the manufactured sand's output quality, has not significantly decreased. "Every time we conduct maintenance on this sand making machine, seeing the solid internal structure that keeps the entire manufactured sand production line running smoothly, we know our initial choice was correct." This "durability" of the sand making plant has not only saved the client from the investment in frequent equipment replacement for their sand making plant, but also ensured the continuous operation of the production line, making project profits more stable.

In fact, the durability of the DS60 Sand Making Plant—a machine designed to be the backbone of any manufactured sand production line—is no accident. From the strict selection of steel strength for key components during the R&D phase, to the repeated verification of welding processes and assembly accuracy that ensure the sand making machine's structural integrity during production, and then to the multiple tests simulating extreme working conditions of a busy manufactured sand production line before delivery, every link is dedicated to ensuring "long-term stable operation" of both the sand making plant and the entire line it supports. The 6,000+ hours of operation data fed back by the client is precisely the inevitable result of these details, which matter greatly for a sand making machine that bears the weight of daily production.

For enterprises looking to build or upgrade a manufactured sand production line, the practical experience of Ninon's DS60 Sand Making Plant may be the most convincing reference: when a sand making equipment can continuously "withstand" high-intensity operations for 8 years as the core of a manufactured sand production line, and its durability is proven by tangible operation hours, choosing it means choosing a "reassurance" not just for a single piece of equipment, but for the entire manufactured sand production line's long-term productivity.

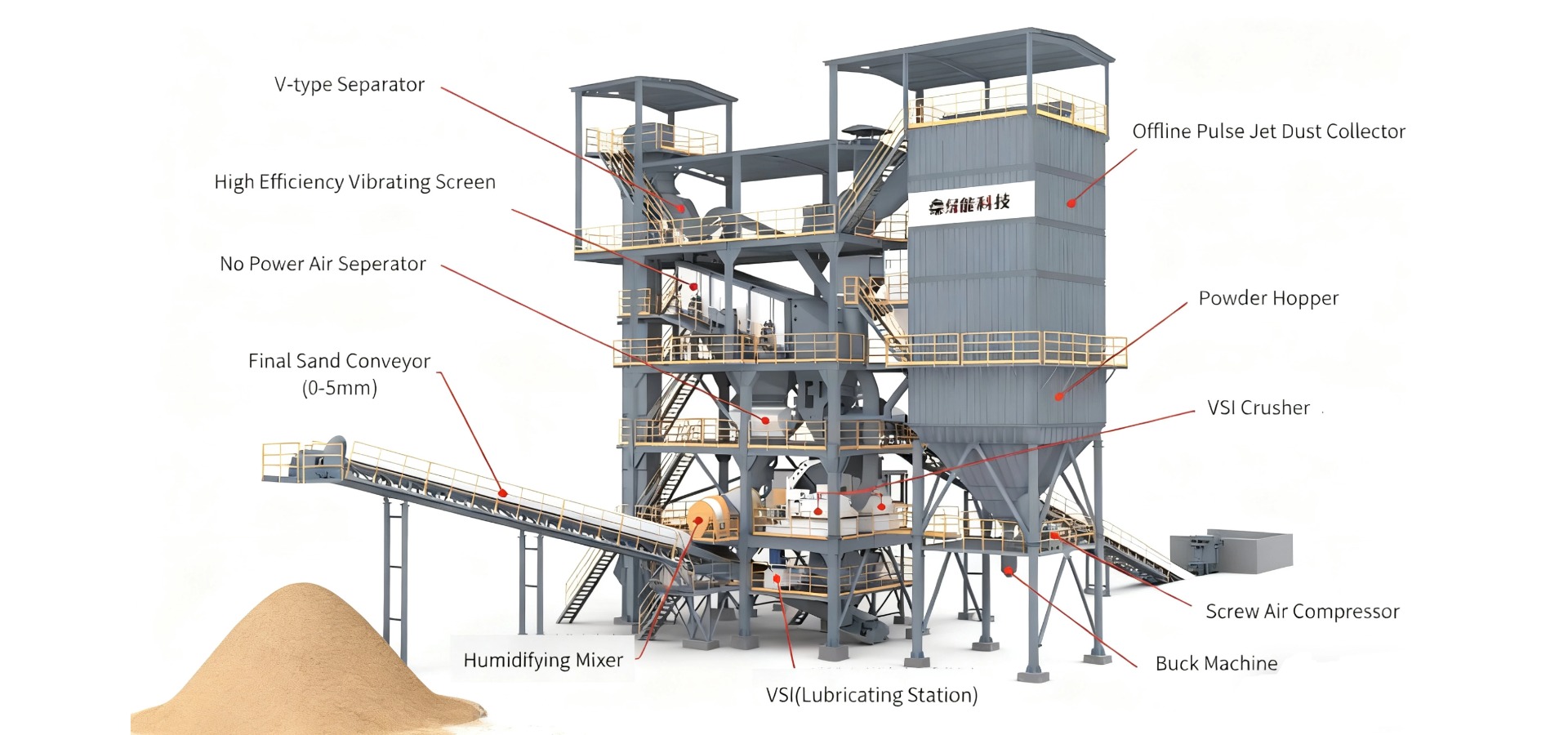

DS series Aggregate Shaping and Sand Making Plant