Terms and Definitions of Construction Sand

Natural Sand

Rock particles with a particle size less than 4.75 mm, formed by rock crushing, weathering, sorting, transportation and accumulation under natural conditions.

Manufactured Sand

Blended Sand

Sand formed by mixing manufactured sand (produced through a vsi crusher in a sand making plant) and natural sand in a certain proportion. This type of sand combines the stability of manufactured sand and the workability of natural sand.

Mud Content

Stone Powder Content

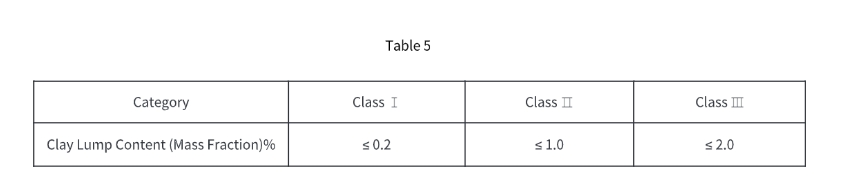

Clay Lump Content

Content of particles in sand that originally have a particle size greater than 1.18 mm and become less than 0.60 mm after soaking in water, elutriation and other treatments. In a sand making plant, raw materials are inspected for clay lump content first, and those with excessive content are pre-treated before entering the sand making machine.

Fineness Modulus

Soundness

Flaky Particle

Lightweight Substance

Alkali-Aggregate Reaction

An expansion reaction that occurs slowly in a humid environment between alkali-reactive minerals in sand and alkalis from concrete components such as cement, mineral admixtures and admixtures, as well as alkalis in the environment, leading to concrete cracking and damage. In a sand making plant, raw materials for the sand making machine are tested for alkali-reactive minerals to avoid this reaction.

Classification and Categories

Classification

Classification by Fineness Modulus

Coarse sand: 3.7 ~ 3.1

Medium sand: 3.0 ~ 2.3

Fine sand: 2.2 ~ 1.6

Extra-fine sand: 1.5 ~ 0.7

Categories

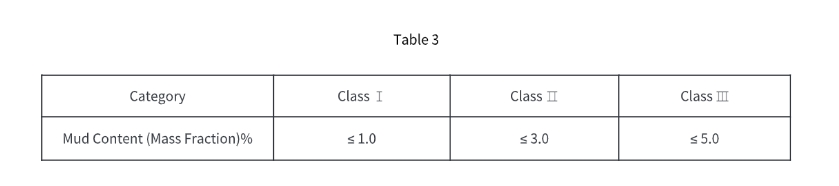

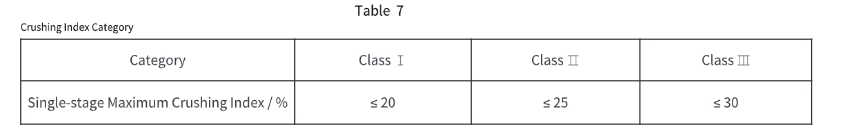

Construction sand is classified into Category I, Category II and Category III according to technical requirements including particle gradation, mud content (stone powder content), methylene blue (MB) value, clay lump content, harmful substances, soundness, crushing index and flaky particle content.

Category I sand: Suitable for high-strength concrete, requiring strict control of particle gradation and stone powder content. It is usually produced by a high-precision sand making machine in a sand making plant, with the vsi crusher ensuring excellent particle quality.

Category II sand: Used for ordinary concrete and mortar, with moderate technical requirements, producible by a standard manufactured sand production line.

Category III sand: Applied to non-load-bearing concrete and backfill projects, with relatively loose requirements, but the sand making machine still needs to control basic particle size.

Particle Gradation

Except for extra-fine sand:

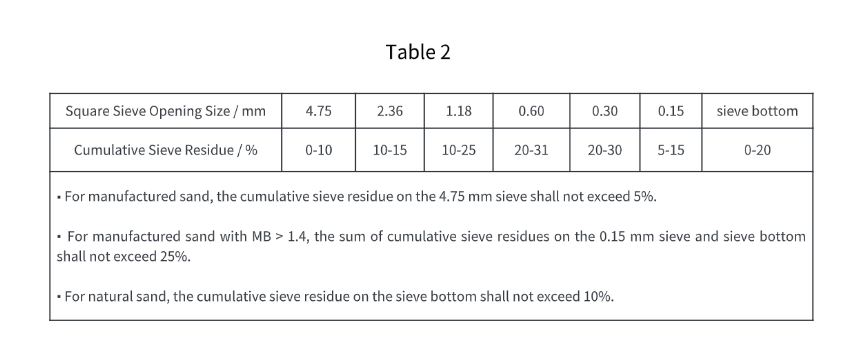

The cumulative sieve residue of Category I sand shall comply with the requirements of Zone 2 in Table 1, and the individual sieve residue shall comply with Table 2. This requires the screening system of the sand making machine in the manufactured sand production line to have high precision.

The cumulative sieve residue of Category II and Category III sand shall comply with Table 1.

The actual particle gradation of sand may deviate from the specified ranges except for the 4.75 mm and 0.60 mm sieve sizes, but the total sum of deviations of cumulative sieve residue across all sieve sizes shall not exceed 5%. In a sand making plant, operators monitor particle gradation in real time and adjust the manufactured sand production line (such as the feeding amount of the vsi crusher) to control deviations.