Currently, the commonly - used sand - making processes in the market are the dry - process sand making and the wet - process sand making. Then, compared with these two processes, which one is more in line with the current sand - making requirements?

The dry sand-making process, developed after and from the traditional wet method, differs mainly in whether water is used to remove fines in a manufactured sand production line. A dry-process manufactured sand production line doesn't use water. It relies on a sand making machine for crushing and shaping, then uses air classification and dust removal to control powder content and remove impurities. A wet-process manufactured sand production line requires a sand washer to rinse the material produced by the sand making machine, effectively removing mud and impurities.

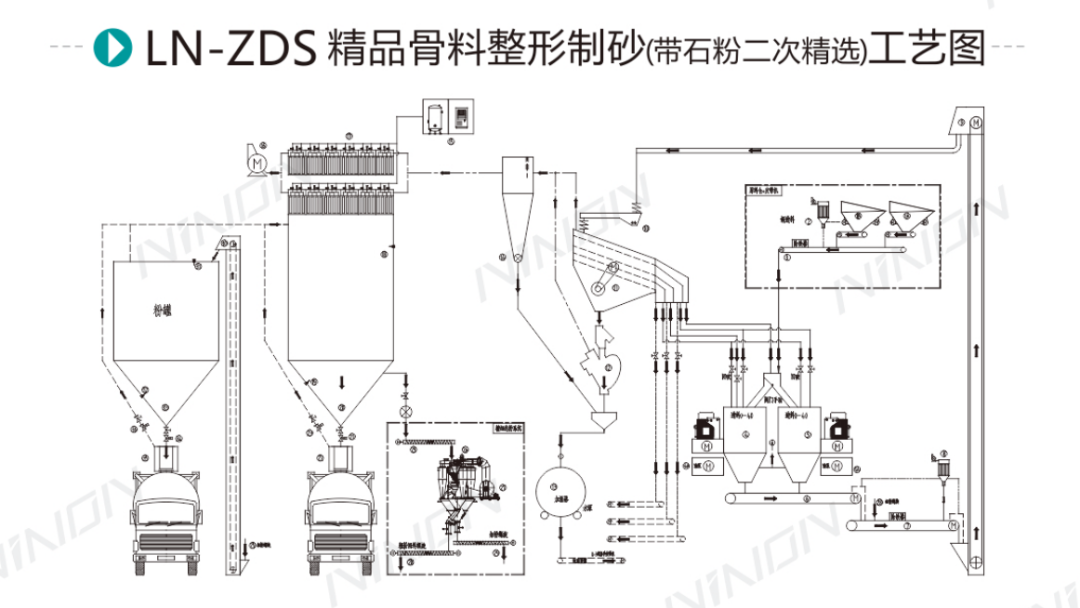

Process Flow

Dry Process Sand Making: A typical manufactured sand production line using the dry process integrates several key components: vibrating feeders, crushers, belt conveyors, sand making machine, vibrating screens, elevators, high-efficiency powder separators, silo groups, and dust collectors. The process usually includes stages such as coarse crushing, medium and fine crushing, and final shaping in the sand making machine.

Wet Proccess Sand-Making: During stone processing, the intense collisions in the sand making machine and the inherent soil content in raw materials result in manufactured sand containing both stone powder and mud powder. While an appropriate amount of stone powder can help fill gaps in concrete, mud powder severely impacts quality. To address this, a manufactured sand production line using the wet process incorporates sand washers to remove impurities, ensuring the final product meets construction standards.

Differences and Advantages

(1) In a dry manufactured sand production line, the powder separator controls stone powder content within national standards, enhancing concrete strength and viscosity. This system processes material from the sand making machine, separating only fines below 0.75mm to create more reasonable particle gradation between 0.75mm and 4.75mm.

(2) In wet manufactured sand production line, both stone powder and mud wash away, reducing cohesiveness and harming gradation. Particles below 0.6mm are typically removed during washing.

Thus, dry-process manufactured sand production line yields better gradation and higher capacity than wet washing, with the sand making machine playing a central role in both methods.

Differences in Investment

The dry-process manufactured sand production line uses a high-efficiency powder separator for sand-powder separation, eliminating the need for large amounts of water for cleaning—slashing overall production costs. Its fully automatic powder separation system targets the output of the sand making machine (the core equipment of the line) to precisely sort powder, directly saving water fees that wet-process lines would incur.

Moreover, since no water is added to the vertical shaft impact crusher (a key component of the sand making machine) during sand making, equipment wear is significantly reduced. This lowers the replacement frequency of vulnerable parts inside the sand making machine, a major cost driver for manufactured sand production line operations. At the same time, wear on parts in the line’s conveying and screening systems is also greatly reduced, further cutting production and processing costs for the manufactured sand production line.

Differences in Environmental Restrictions

Dry sand-making—with the sand making machine as core and part of the manufactured sand production line—avoids environmental limits. It works even in water-scarce areas, unlike wet-process manufactured sand production lines that need abundant water. Wet lines use lots of water (risking pollution) and stop in northern winters due to freezing. But dry-process sand making plant, where the sand making machine runs without water, operate normally in cold weather. Thus, dry sand-making gets government approval easier for environmental compliance, ideal for regions like north of the Yellow River.

Differences in Environment Performance Excellence

The dry sand-making production line does not require water for cleaning. Moreover, it can rationally utilize the stone powder generated during production, thereby saving water and mineral resources to a certain extent. With no discharge of sewage or sludge, it is more environmentally friendly than the wet-process production line.

Differences in Economic Value

The by-product of the dry sand-making production line is stone powder, which is largely lost in water-washed sand production lines. The dry sand-making process is equipped with powder storage tanks to collect such stone powder, which also has high economic value.

Conclusion

From the above analysis, it can be seen that the dry sand-making process has advantages over the wet sand-making process. The sand produced by the dry sand-making process is of excellent quality, with reasonable gradation, solid texture and good particle shape. Meanwhile, the operation process is smoother, featuring energy conservation, consumption reduction and environmental friendliness. In addition, it can save working steps, with no discharge of sewage or sludge, thus causing no pollution to the environment, ecology, water flow, etc., and achieving good environmental protection effects. Moreover, the investment cost is relatively low, making it highly popular in the industry.