On the afternoon of August 2, 2023, a delegation from the Industrial Solid Waste Network visited Fujian Ninon Technology Co., Ltd. (hereinafter referred to as "Ninon") for in-depth inspection and exchange activities. The delegation was warmly received by Mr. Wang Jianxiong, General Manager of Ninon. Throughout the event, which included a technical symposium, a tour of the company’s exhibition hall, and an on-site inspection of key engineering cases, the delegation gained a comprehensive and detailed understanding of Ninon’s operational status, especially its technological advantages in the manufactured sand production line and tailings slag processing equipment, as well as the latest progress in comprehensive solid waste utilization technologies.

Both parties first held a technical exchange seminar in the conference room. General Manager Wang gave a comprehensive introduction to the company's development history, technological innovation of products, R&D capabilities, production processes, comprehensive utilization of solid waste, after-sales services, etc., and provided professional answers to the questions raised by the delegation.

The exchange kicked off with a technical seminar held in Ninon’s conference room. General Manager Wang Jianxiong delivered a systematic introduction to the company’s development trajectory, core technological innovations, R&D team strength, standardized production processes, and whole-life-cycle after-sales service system. He emphasized that Ninon has long focused on addressing industry pain points in solid waste recycling, with its independently developed manufactured sand production line and tailings slag processing equipment serving as the core pillars of its business.

The manufactured sand production line, he explained, adopts intelligent control systems to realize high-efficiency, low-pollution processing of construction waste and mineral waste into high-quality manufactured sand that meets national construction standards, effectively alleviating the shortage of natural sand resources. Meanwhile, the tailings slag processing equipment integrates crushing, sorting, and purification technologies, enabling the full utilization of tailings slag—by-products of mineral processing—converting it into usable building materials or raw materials for other industries, thus significantly reducing solid waste stockpiling and environmental pressure.

During the Q&A session, the delegation raised questions about the production efficiency of the manufactured sand production line, the adaptability of the tailings slag processing equipment to different types of tailings, and the economic benefits of project applications. General Manager Wang provided professional, data-supported answers, which were highly praised by the delegation.

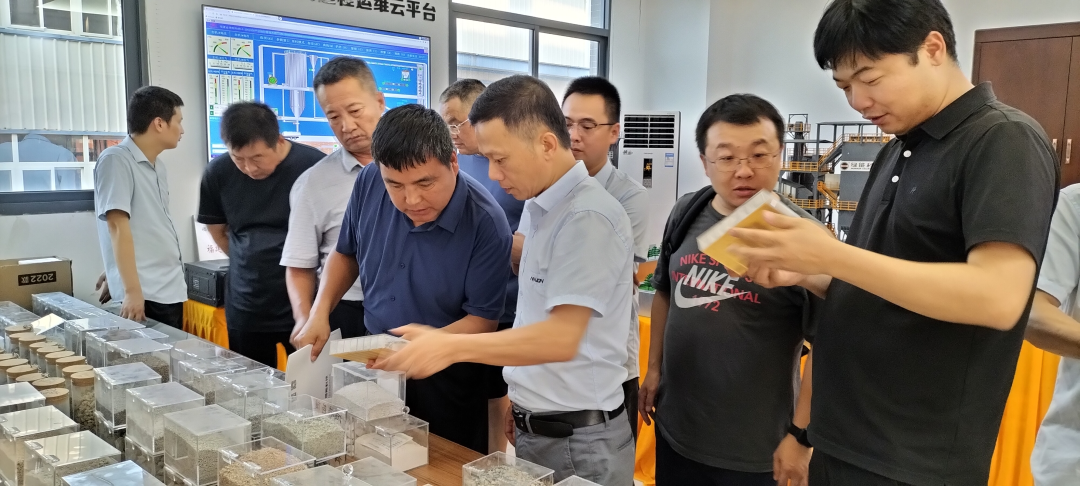

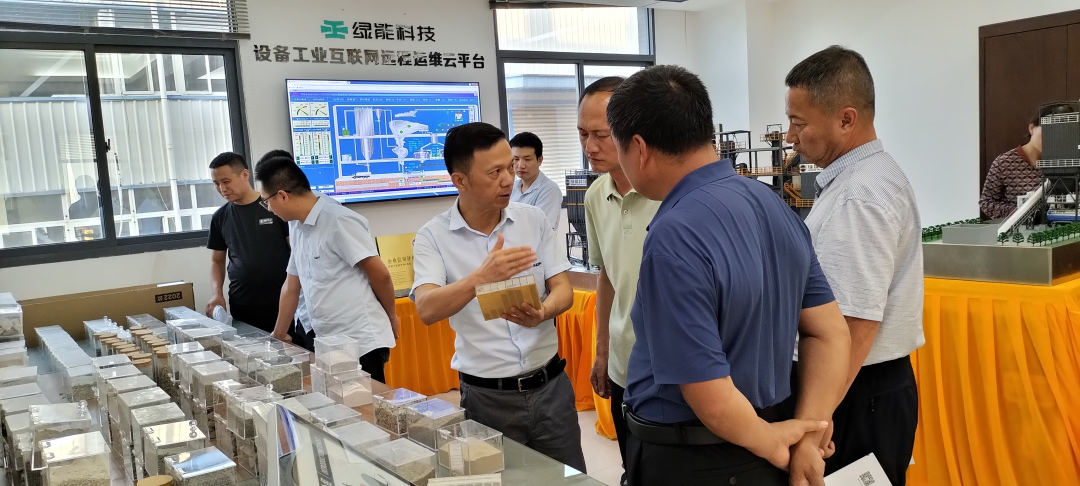

After the seminar, under the guidance of General Manager Wang, the delegation visited Ninon’s product exhibition hall. Here, physical models and technical demonstration videos of the manufactured sand production line and tailings slag processing equipment were the focus of attention. The delegation members carefully observed the structural design of the equipment, inquired about key technical parameters, and expressed admiration for the innovation and practicality of Ninon’s technologies.

Later, the delegation traveled to Quanzhou to conduct an on-site inspection of an engineering project where Ninon’s manufactured sand production line and tailings slag processing equipment were in operation. Witnessing the equipment efficiently processing solid waste into high-value products on-site, the delegation gained a more intuitive understanding of the actual application effects and market potential of Ninon’s technologies. During the on-site exchange, both parties had in-depth discussions on issues such as project cooperation models, equipment maintenance, and follow-up technological upgrades.

At the conclusion of the inspection, the delegation expressed high recognition and affirmation of Ninon’s achievements in solid waste comprehensive utilization, particularly its technological breakthroughs in the manufactured sand production line and tailings slag processing equipment. They stated that Ninon’s technologies align with the national policy direction of "dual carbon" and circular economy development, and they hoped to explore in-depth cooperation opportunities with Ninon in the future, strengthen technical exchanges and resource sharing, and jointly promote the overall progress of the comprehensive solid waste utilization industry. This collaboration, they believed, would not only drive industrial upgrading but also create greater economic benefits and social value for the society.