Ruian Anchang LNZDS-1030 Engineering Case

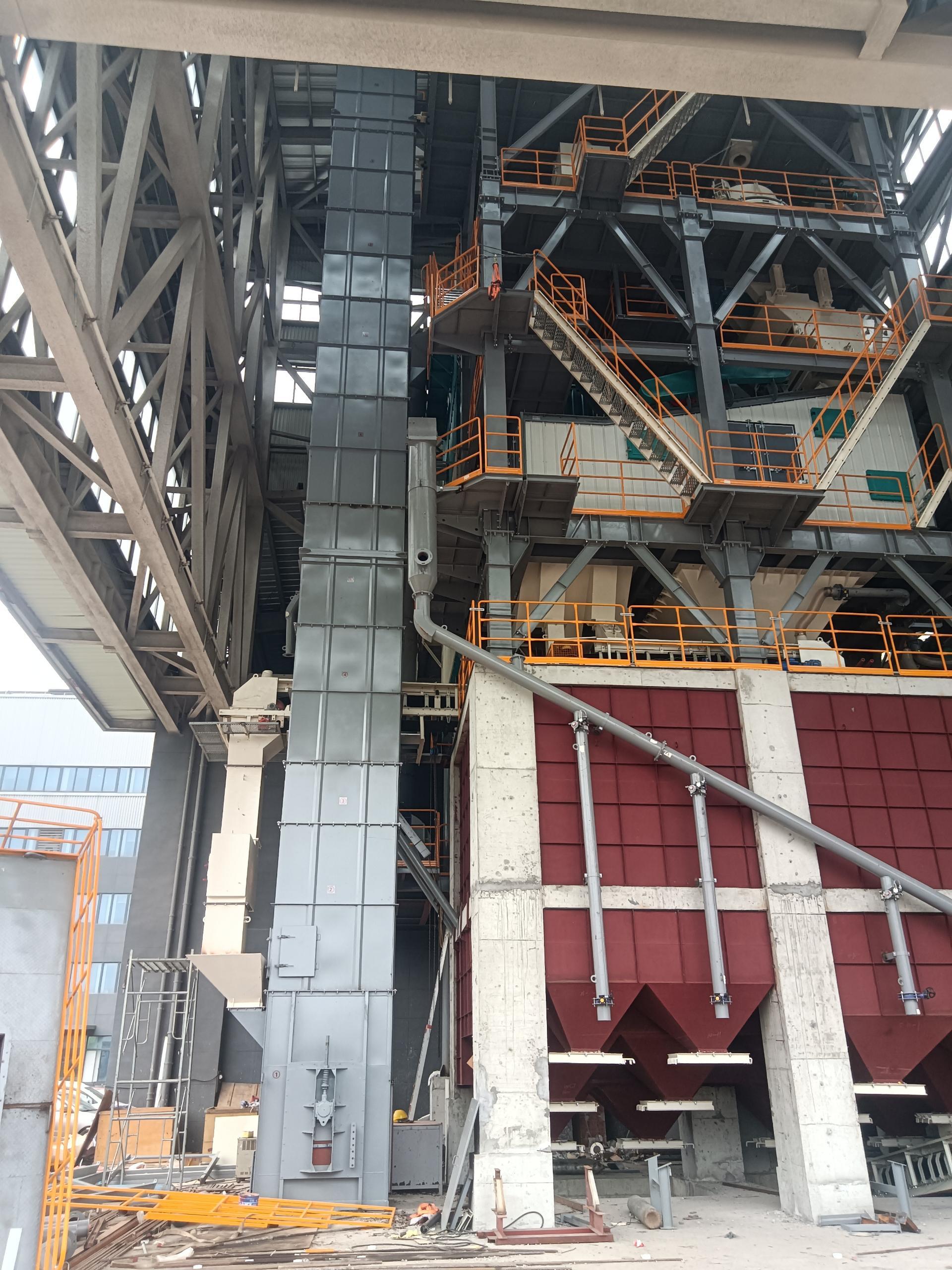

The LNZDS-1030 sand making plant, installed in Ruian City, Zhejiang Province, was designed and commissioned to meet the growing demand for high-quality recycled construction aggregates and materials for road construction applications. This advanced facility successfully fulfills the customer's core requirements for excellent finished particle shape, a wide range of product specifications, and a reliable production capacity aligned with both current project needs and long-term operational goals. By converting construction and demolition waste into usable sand and aggregate, the sand making plant not only contributes to resource recycling but also supports the region's environmental and infrastructure development initiatives.

The sand making plant with multi-stage screening and grading systems to produce well-graded, cubical sand with superior particle shape. This is crucial for applications where the consistency and structural integrity of the final material are of utmost importance, such as high-performance concrete and road base layers. Additionally, the system allows for adjustable product output, enabling the production of various sizes and specifications of sand and gravel to suit diverse engineering standards. Whether the need is for coarse aggregates, fine sand, or a specific gradation mix, the sand making plant can quickly adapt, offering maximum production flexibility.

One of the key advantages highlighted by the customer is high level of automation. From material feeding and crushing to screening and final output, the entire process is controlled by an intelligent monitoring system that ensures optimal equipment performance, real-time diagnostics, and consistent product quality. This automation significantly reduces manual labor, minimizes operational errors, and improves overall production efficiency. The sand making plant is also equipped with energy-efficient motors and wear-resistant components, helping to lower operating costs and extend service life.

Environmental compliance was a major consideration during the plant's development. Equipped with modern dust suppression systems and noise control features, the sand making plant operates in accordance with strict environmental regulations, ensuring minimal impact on the surrounding community. Enclosed structures and sealed conveyor belts reduce the dispersion of dust and fine particles, contributing to a cleaner work environment and more sustainable production.

Customer feedback has been overwhelmingly positive. In addition to recognizing the high performance of the equipment, the client praised the professionalism and responsiveness of Ninon's service team. From initial consultation and layout design to installation, commissioning, and ongoing technical support, the after-sales team provided timely assistance and effective solutions at every stage of the project. Fast response times and proactive follow-ups ensured a smooth startup and trouble-free operation, which contributed to a high level of overall satisfaction.