Brief Introduction

The VSI crusher, also widely recognized as the impact sand making machine, stands as an advanced high-energy and low-consumption sand making equipment that plays a pivotal role in modern manufactured sand production lines. Its performance holds an irreplaceable position among various ore fine crushing devices, solidifying its status as the most effective, practical, and reliable sand making machine in the field.

Application Scenarios of Crushers

Ninon's VSI crushers, as core components of many manufactured sand production lines, are extensively utilized in processing metal and non-metallic ores, cement, refractory materials, abrasives, glass raw materials, construction aggregates, artificial sand, river pebbles, mountain rocks (including limestone, granite, basalt, diabase, andesite, etc.), ore tailings, and stone chips. These versatile sand making machines convert such materials into artificial sand, construction aggregates, highway pavement materials, cushion materials, as well as aggregates for asphalt concrete and cement concrete. Beyond that, VSI crushers are key in the fine crushing and coarse grinding operations of various metallurgical slags within manufactured sand production lines.

Notably, when handling medium-hard, extra-hard, and abrasive materials like silicon carbide, emery, sintered bauxite, and magnesia, Ninon's VSI crushers outperform other types of sand making machines, making them indispensable in high-demand manufactured sand production lines. When paired with hydraulic protection jaw crushers, these VSI crushers efficiently process various metallurgical slags, further enhancing the flexibility of manufactured sand production lines. They are particularly well-suited for producing construction sand and road-building sand-stone, making them a top choice for optimizing manufactured sand production line efficiency.

Woring Principle of the VSI Crusher

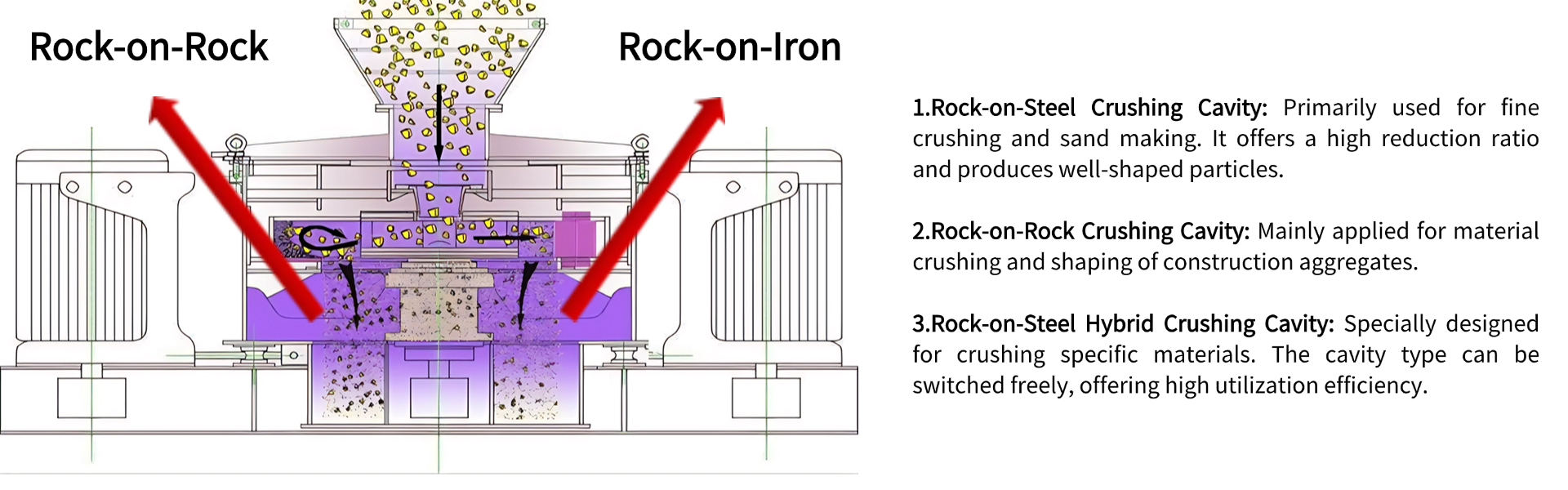

In a typical manufactured sand production line, materials first enter the center of the VSI crusher's high-speed rotating rotor through a distributor. The blow bars on the rotor hurl the materials out at an extremely high speed— a critical step that sets this sand making machine apart. As stones fall naturally, they collide with those accelerated and thrown by the rotor, then impact the material layer or impact plates inside the crushing chamber. This repeated collision and friction within the chamber are fundamental to the crushing process in a VSI crusher.

Simultaneously, stone materials directly enter the high-speed rotating rotor from the upper part of the sand making machine. Under high-speed centrifugal force, they collide at high velocity with another portion of target stones diverted around the turntable, undergoing high-density crushing— a key mechanism that ensures the VSI crusher's efficiency in sand making plant. After mutual impact, the materials form a vortex motion between the turntable and the machine shell, leading to multiple additional impacts, friction, and crushing cycles.

Finally, the crushed sand particles in the VSI crusher are sorted for particle size control: some models use a bottom sieve plate, while others employ air classification. Qualified materials are then discharged, ready to integrate into the next stage of the manufactured sand production line, highlighting the VSI crusher's role as a cornerstone in consistent and high-quality sand production.

VSI Crusher: Empowering Efficient Sand Production

1. Low Cost Investment

Ninon's sand making machines with VSI crusher feature reliable operation, user-friendly control, high efficiency, and energy conservation. They can be combined with various models according to different process requirements, resulting in low investment in sand making costs.

2. Excellent Particle Shape of Crushed Products

With high crushing efficiency and low energy consumption, the crushed products have uniform particle size, natural particle shape, and solid, stable material quality. Therefore, they are often applied in construction and engineering fields with strict requirements for sand and gravel materials.

3. Easy Operation and Convenient Maintenance

The sand making machine is easy to operate and use. Equipped with a hydraulic cover-opening device, it enables quick and convenient inspection, repair, and replacement of internal components in the crushing chamber, saving time and effort.

4. Sophisticated Technology, Energy Conservation and Environmental Protection

The application of riveting technology, as well as the adoption of professional processes such as surface sandblasting for rust removal and painting, enhances both the internal quality and external appearance of the equipment.