Working Principle and Structural Design

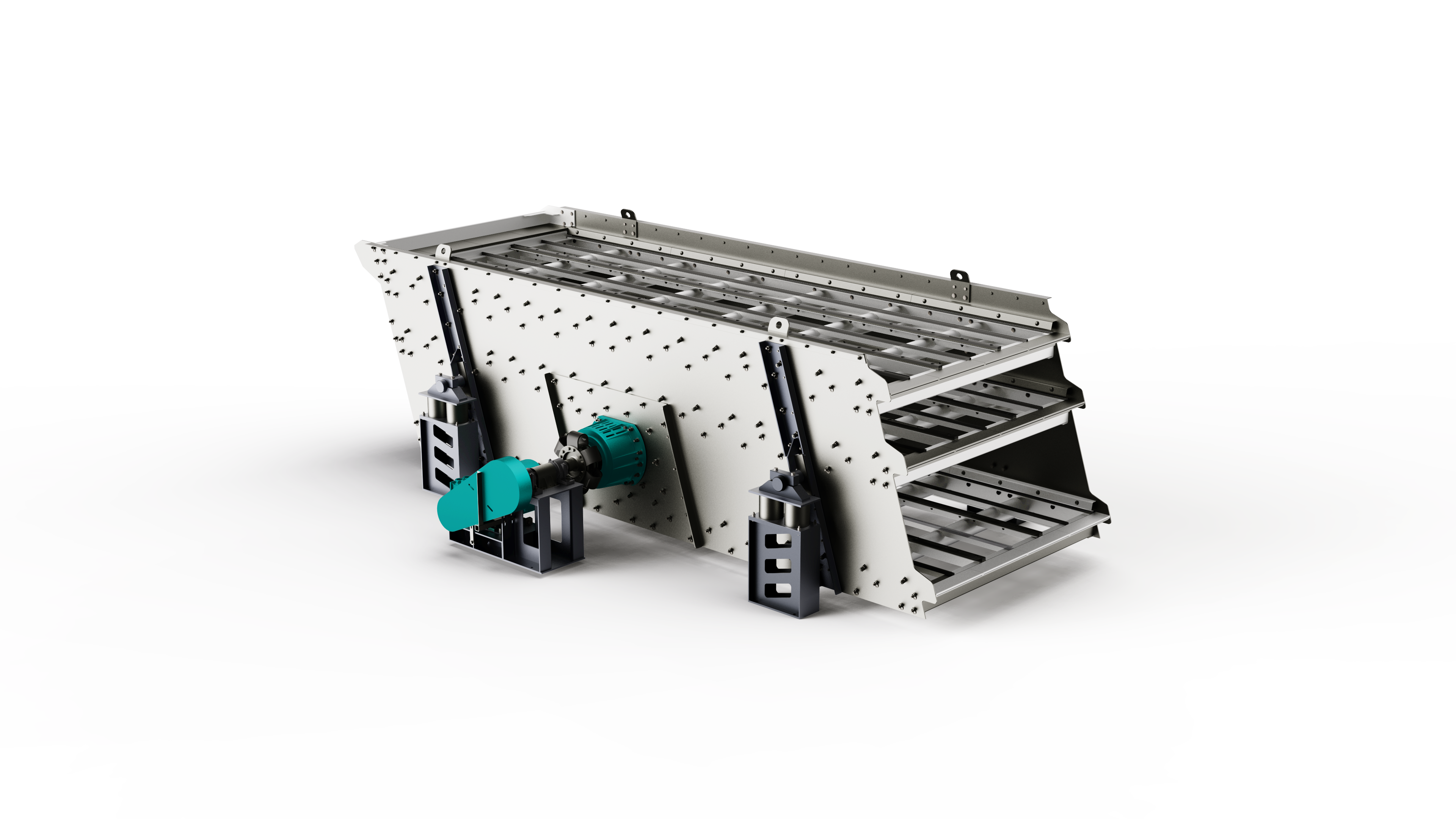

1. Circular Vibrating Screen

(1) Motion Trajectory: Generates three-dimensional elliptical motion via an eccentric block vibrator (the major axis is the throwing direction, and the minor axis is the vibration direction), enabling materials to move forward in a spiral jumping manner.

(2) Power System: Equipped with single-shaft or double-shaft vibrators, adopting gear synchronization or universal joint transmission. The amplitude ranges from 4 to 8mm, and the frequency is 700-1000r/min.

(3) Screen Inclination Angle: Adjustable between 15° and 25°, with the exciting force regulated by adding or removing counterweights.

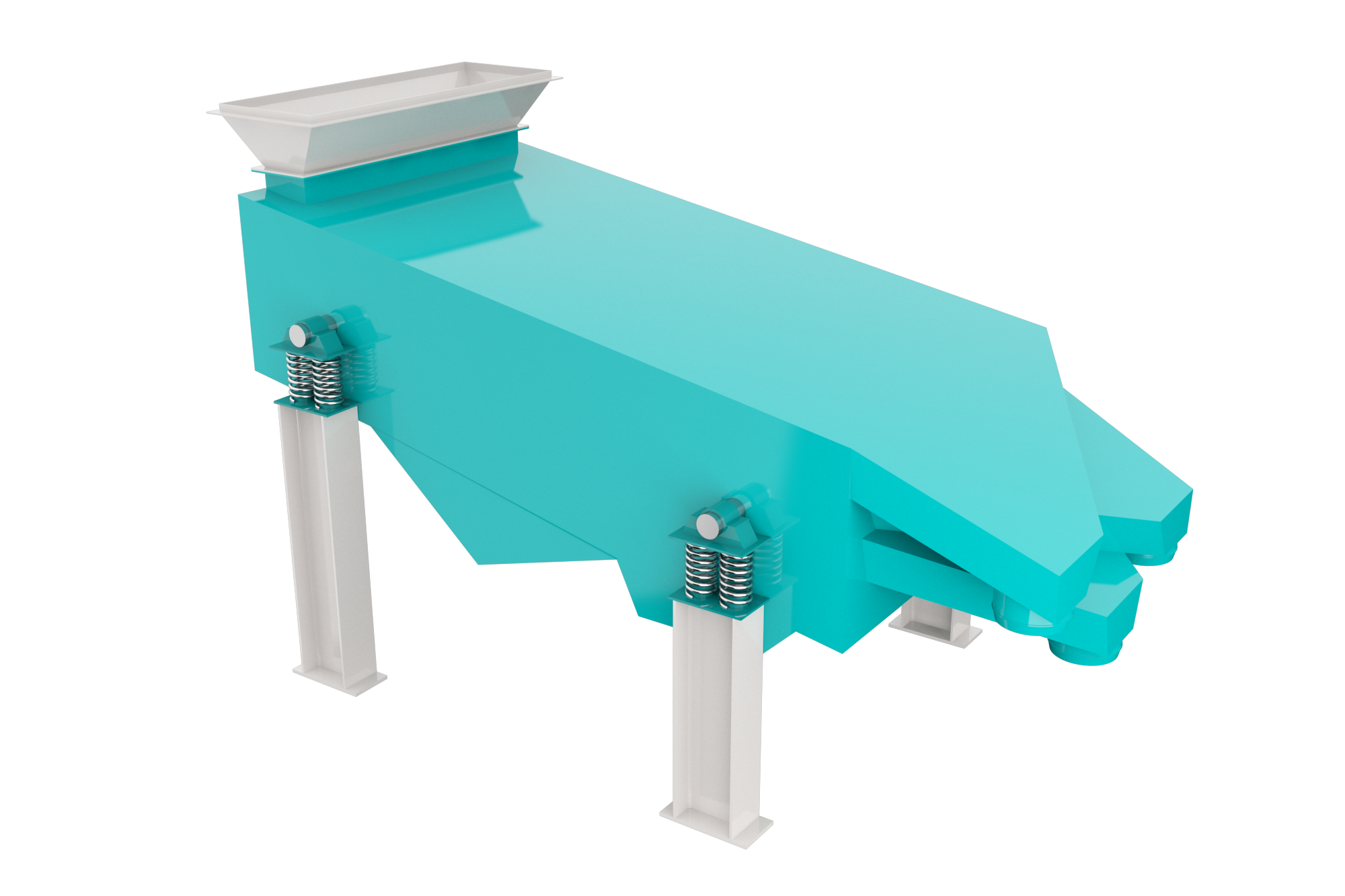

2. Linear Vibrating Screen

(1) Motion Trajectory: Two motors rotate in opposite directions to generate directional linear vibration, allowing materials to perform parabolic jumping motion on the screen surface.

(2) Power System: Equipped with two symmetrically installed vibrating motors of the same model, with an amplitude ranging from 2 to 6mm and a frequency of 900-1500r/min.

(3) Screen Inclination Angle: Adjustable between 0° and 10°, and the exciting force is controlled by adjusting the angle between the eccentric blocks of the motors.

Performance Parameters Comparison

Indicators | Circular Vibrating Screen | Linear Vibrating Screen |

Processing Capacity | 100-1200 t/h | 50-800 t/h |

Screening Efficiency | 85%-92% (for medium-fine grading) | 90%-95% (for dry screening) |

Applicable Particle Size | 0.074-50mm | 0.1-300mm |

Power Consumption | 7.5-55kW | 5.5-37kW |

Noise Level | ≤80dB | ≤75dB |

Maintenance Cost | Bearing service life ≥8000 hours | Screen replacement cycle: 3-6 months |

Typical Application Scenarios

1. Application Scenarios for Circular Vibrating Screens

(1) Mining Industry: Coarse, medium, and fine grading of iron ore and copper ore (e.g., 0-5mm, 5-20mm, 20-40mm).

(2) Building Materials Industry: Gradation adjustment of machine-made sand (fineness modulus 2.3-3.0) and screening of cement clinker after cooling.

(3) Environmental Protection Field: Impurity separation of recycled aggregates from construction waste.

2. Application Scenarios for Linear Vibrating Screens

(1) Coal Industry: Raw coal grading (separation of +50mm lump coal and -50mm fine coal) and coal slime dewatering.

(2) Metallurgical Industry: Cooling and screening of sinter (temperature ≤150°C).

(3) Grain Processing: Impurity removal and grade screening of soybeans and corn.

Selection Decision Process

Step 1: Determine Material Characteristics

(1) Particle Size Range:

◆ Fine particles (<3mm) → Prioritize circular motion screens (multi-layer grading).

◆ Coarse particles (>10mm) → Select linear vibrating screens (large processing capacity).

(2) Moisture Content:

◆ Wet and sticky materials (moisture content >8%) → Linear vibrating screens (equipped with bouncing balls for screen cleaning).

◆ Dry materials → Circular motion screens (high inclination angle to prevent clogging).

Step 2: Match Production Requirements

(1) Processing Capacity:

◆ <500t/h → Linear vibrating screens (low energy consumption).

◆ ≥500t/h → Circular motion screens (stable efficiency).

(2) Screening Precision:

◆ Required error ±0.5mm → Linear vibrating screens (small screen inclination angle, long material residence time).

◆ Allowable error ±1mm → Circular motion screens.

Step 3: Evaluate Long-Term Costs

(1) Initial Investment:

◆ Circular motion creens are 10%-15% more expensive (complex structure).

◆ Linear vibrating screens have lower maintenance costs (modular design).

(2) Energy Consumption Ratio:

◆ Circular motion screens: 0.3-0.5kW·h per ton of processing.

◆ Linear vibrating screens: 0.2-0.4kW·h per ton of processing.

Conclusion

Boasting efficient classification and stable adaptability, the circular vibrating screen (also known as circular motion screen) shines as a "high-performance expert" in mining multi-particle grading; the linear vibrating screen, with precise screening and low consumption, is the "powerful leader" in coal separation. —each circular vibrating screen and linear vibrating screen excels in its field.